Metals Billet Hot Forging Furnace with Induction for the heating of copper/aluminum/iron steel billets before hot forming

Induction heating is widely employed in metals billet hot forging industry to heat billet that is to be forged in hot. In the steel working industry, hot forging steels are heated to temperatures around 1000 oC-1250 oC according to carbon content and the alloying elements. The hot forging process requires high temperature heating of billet uniformly both along the cross sectional side and traverse side of the billet. Generally the initial temperature of the billet is in the room temperature and it is required to heat above the recrystallization temperature for hot forging process. There are various ways to heat metal in hot forging including the induction heating, gas fired furnace, oil fired furnace, infrared heater and the electrical resistance heater. Induction heating has various advantages over the other methods of heating in hot forging. First of all, induction heating systems create high heat intensity very quickly at defined part of the metal. Additionally, induction heating systems are fast starting systems, since these systems do not need preheating time as in the furnace heating. Also, heating time is incompatibly short against the other methods. Compared to the gas and oil furnace heating, controlling and repeating the same heating condition for different time is easier to achieve. Automation can be applied to the induction heating systems. It will require minimum shop floor space.

Induction heating is also more energy efficient and more environmental friendly. There will not be any harmful combustion emission to the environment as in the gas and oil furnace heating. Further more the gas fired furnaces result with poor surface quality due to scale formation. The induction heating provides significant reduction in scale formation and decarburization on the heated billet.

Product Description

For heating various of bar materials: such as steel & iron, bronze, brass, aluminum alloy, etc.

Picture just for reference, color is changable with different power.

Functions and special specifications customized by customer's requirements.

Features and Advantages:

1.Automatic:Automatic feeding, automatic selection of the work-piece is good or bad, automatic measurement of temperature, automatic discharge.

2. Integrated design: Save installation time,cost and space.

3. Operation panel embedded displays machine operating states, to facilitate fault diagnosis.

| |

Features |

Detail |

| 1 |

Heating fast and stable |

saving 20%- 30% electric energy than traditional way;

High efficiency and low energy consumption |

| 2 |

Small in size |

Easy to install, operate and repair |

| 3 |

Safe and reliable |

No high voltage, very safe to your workers. |

| 4 |

A cooling circulation system |

Able to operate continuously 24 hours |

| 5 |

complete self-protect

function |

many types of alarm lamps:

over-current, over-voltage, over hot, water shortage etc. These lamps can control and protect machine. |

| 6 |

Environmental protection |

Almost no oxide layer,

produced no exhaust, no waste-water |

| 7 |

IGBT Type |

Avoid the interruption of unrelated electric net;

Ensure the long-life of the machine. |

Parameter of metals billet hot forging furnace:

|

DW-MF-200 |

DW-MF-250 |

DW-MF-300 |

DW-MF-400 |

DW-MF-500 |

DW-MF-600 |

| Input Voltage |

3phases, 380V/410V/440V , 50/60Hz |

| Max Input Current |

320A |

400A |

480A |

640A |

800A |

960A |

| Oscillating frequency |

0.5KHz^20KHz ( Oscillating frequency will be customized according to the size of heating parts) |

| Duty Cycle Loading |

100%,24h continuously work |

| Cooling Water Desires |

0.1MPa

|

| Dimension |

Host |

1000X800X1500mm |

1500X800X2800mm |

850X1700X1900mm |

| Extension |

extension will be customized according to the material and size of heating parts |

| Weight |

110kg |

150kg |

160kg |

170kg |

200kg |

220kg |

| Depend on the dimension of extension |

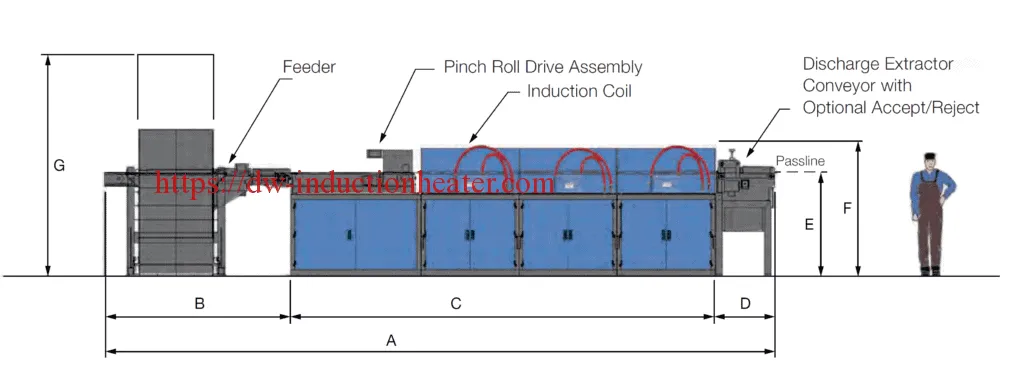

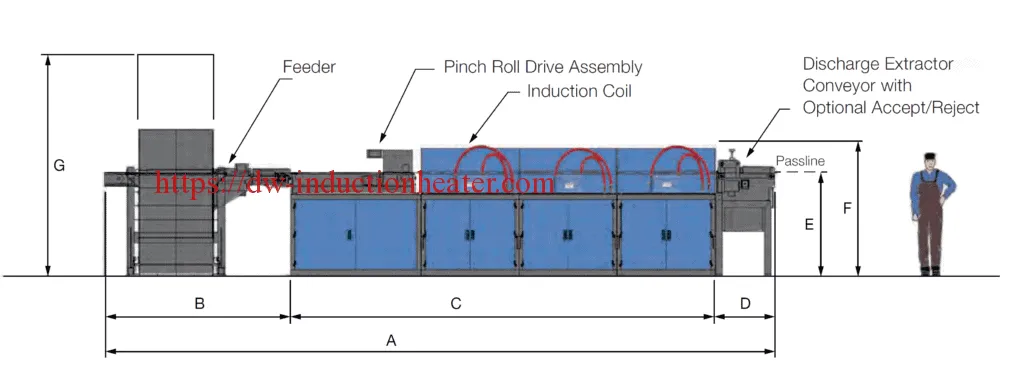

In the induction metals billet hot forging furnace the whole of the billets or slug is heated. Normally for short billets or slugs a hopper or bowl is used to automatically present the billets in line to pinch rollers, chain driven tractor units or in some cases pneumatic pushers. The billets are then driven through the coil one behind the other on water cooled rails or ceramic liners are used through the coil bore which reduce friction and prevent wear. The length of the coil is a function of the required soak time, the cycle time per component and the length of the billet. In high volume large cross section work it is not unusual to have 4 or 5 coils in series to give 5 m (16 ft) of coil or more.