2021年11月17日星期三

Induction Brazing Stainless Steel To Brass

Induction Brazing Stainless Steel To Brass,Copper With Induction Heating Equipment

Research Objective

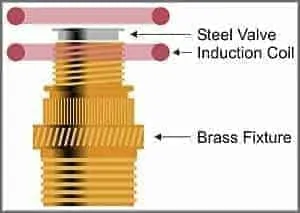

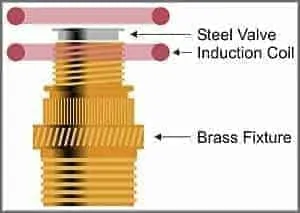

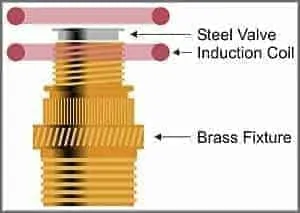

To braze a stainless steel valve seat to a brass plumbing fixture in an oxygen atmosphere and improve assembly reliability.

Parts & Materials Description

Stainless steel valve, 0.25” ID threaded brass plumbing fixture, black flux, braze ring preforms

Temperature Required

1325°F

Induction Heating Equipment

DW-UHF-6kW-III RF induction heating power supply, two-turn helical inductor (coil)

Operating Frequency

300 kHz Heating

Procedure

The testing was done in an open air atmosphere. A specially-designed, two turn helical inductor was used to provide optimal heating to the joint area of the plumbing assembly. Initial tests were conducted with bare parts and temperature sensing paints to establish time-to-temperature and heating profiles. Next the parts were placed in position with a joint clearance of .002” to .003”. The braze ring preform was positioned and black flux was applied to the assembly. RF heat was applied with the RF power supply for 7 seconds to reach the brazing temperature of 1325°F. At this temperature the braze alloy flowed into the joint and formed a strong bond.

Conclusion

Consistent, repeatable results were achieved at 1325°F within 7 seconds. The braze flowed well. Induction brazing produces a strong, clean joint which is ideal for this type of consumer product.

关注者

博客归档

-

▼

2021

(398)

-

▼

十一月

(190)

- high frequency induction soldering wire to connector

- Induction Melting Aluminum

- What Is Induction Heating Coil&Inductor?

- Induction Melting Copper

- Soldering Solar Panels With Induction

- Induction Melting Brass

- High frequency induction brazing steel tube to ste...

- Induction Melting Gold

- Induction Brazing Basics

- Induction Melting Silver

- Induction Brazing Carbide Tipping on Cutting Steel...

- Induction Melting Stainless Steel

- Induction Drying Grain with Induction Heating method

- Induction Heating Turbine Fan For Welding

- Induction Brazing Carbide to Steel

- Induction Heating Titanium Blade

- Induction Annealing Steel Wire

- Induction Heating Steel Rods

- Induction Heating Wires For Hot Heading

- Induction Heating Copper Wire for Stripping

- What is induction annealing?

- Induction Heat setting Nitinol

- Induction Brazing Aluminum Pipes

- Induction Heating Wire Stripping

- Induction Shrink Fitting Steel Tube

- Induction Heating System Topology Review

- Induction Heating the end of catalytic converter

- Induction Hardening Surface Process

- Induction Heating Aluminum Automotive Wheel Hub

- Induction heating of aluminium billets

- Induction heating of cylindrical nonmagnetic ingots

- Advantages of Induction Heating

- Induction Heating End of Rods,Billets,Bars

- Induction Brazing Principle-Theory

- induction heating graphite carbon

- Induction Brazing Carbide To Stainless Steel

- induction heating hot rolling

- Brazing Brass to Aluminum with Induction

- induction heating rivets

- Induction Brazing copper to copper pipes

- Induction heating springs of automotive

- Induction inline wire heating process

- Induction Heating Aluminum

- Induction forging and induction hot forming

- Induction Heating Steel Handle For Bending

- Brazing Copper Tube with Induction

- induction heating steel plate

- Induction Shrink Fitting Aluminum Pump Housing Part

- Induction Heating Inner of Steel Liners

- Induction Heating Theory PDF

- induction heating aluminium

- aluminum scrap melting induction furnace

- Induction Heating Sealing

- Brazing Copper Tube to Brass Fitting With Induction

- Induction Hardening

- Induction Shrink Fitting Steel Tube

- Induction Bending Pipe-Tube

- Induction Hardening Saw Blades

- Induction Soldering Cables to Terminals

- Induction Hardening Gears Teeth

- high frequency induction hardening camshafts process

- Induction Hardening Knife Blade

- Plastic Injection Molding with Induction Heating

- Hardening Stainless Steel Knife Blades With Induction

- Induction Heating Automotive Motor

- Induction Hardening Cast Iron

- Induction Soldering Cables to Terminals

- Induction Hot Forming Titanium Rod

- Brazing Copper Assemblies With Induction

- Induction Forging

- induction heating medical and dental applications

- Induction Forging Steel Strip

- RPR Induction Stripping-Induction Rust & Paint Coa...

- Induction Forging Steel Rod End

- Brazing Wire to Copper Bar With Induction

- Induction Forging Titanium Rods

- Induction Brazing Steel Tips

- Induction Hot Forming Stainless Steel Tape

- PDF of Induction Heating Principle and Applicatons

- Induction Forging Billets

- Magnetic Induction Heater Manufacturer

- Induction Brazing

- Induction Annealing Stainless Steel Tubes

- Induction Brazing Stainless Steel Tubes

- induction heating nanoparticle solution

- Induction Brazing Stainless Steel To Brass

- Induction Brazing copper wire to copper cylinder

- Induction Brazing Copper Tube

- Induction Brazing Copper Assembly

- Induction Hot Forming Steel Pipe

- Induction Brazing Stainless Steel Tools

- Handheld Induction Brazing Copper Tubing and Fitting

- Induction Brazing Copper

- Induction Annealing Stainless Steel Tubes

- Induction Brazing Copper Billets

- Automatic Induction Forging Video

- Brazing Diamond Tools With Induction

- Technology of Induction Forming Steel Plate

- Induction Brazing Shaft

- Induction Hardening Steel Part with High Frequency...

-

▼

十一月

(190)

我的简介

- HLQ induction heating machine

- HLQ induction heating machine manufacturer provides the service of induction brazing,melting,hot forming,hardening surface,annealing,shrink fitting,PWHT,etc.