Temperature 1100-1450ºF (593-788ºC)

Frequency 150 kHz

Equipment •DW-UHF-20kW induction heating system, equipped with a remote workhead containing one 0.66μF capacitor.

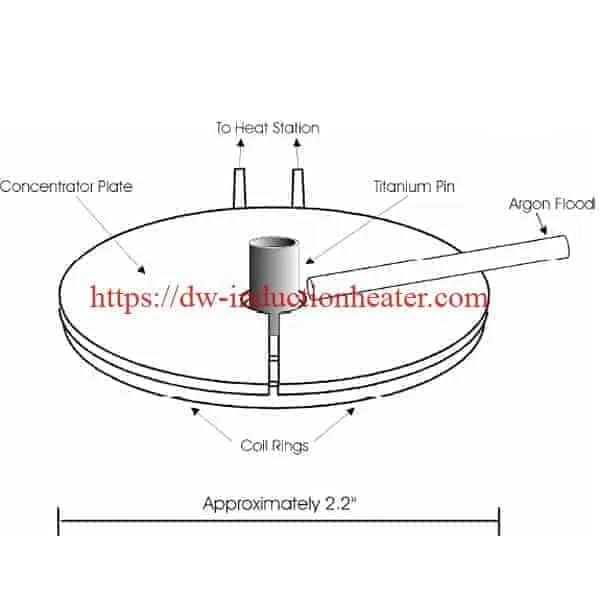

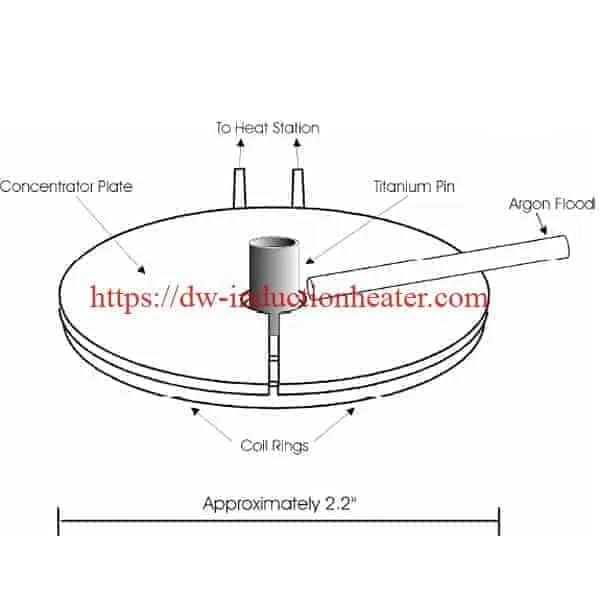

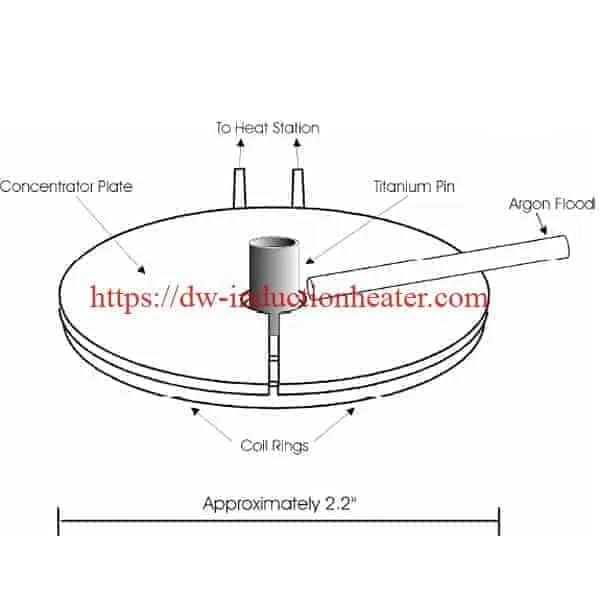

• An induction heating coil designed and developed specifically for this application.

Process A three turn concentrator plate coil is used to heat the fastener for 0.2 seconds. This is an automated process that includes robotic placement of parts in the coil from a bowl fed track while Argon gas is flooded across the part to prevent oxidation. The parts are processed at a rate of 1000 parts per minute.

Results/Benefits Induction heating provides:

• Can be incorporated easily with pick and place robotics.

• Flameless process.

• Heating is limited to the specific area.

Temperature 1100-1450ºF (593-788ºC)

Frequency 150 kHz

Equipment •DW-UHF-20kW induction heating system, equipped with a remote workhead containing one 0.66μF capacitor.

• An induction heating coil designed and developed specifically for this application.

Process A three turn concentrator plate coil is used to heat the fastener for 0.2 seconds. This is an automated process that includes robotic placement of parts in the coil from a bowl fed track while Argon gas is flooded across the part to prevent oxidation. The parts are processed at a rate of 1000 parts per minute.

Results/Benefits Induction heating provides:

• Can be incorporated easily with pick and place robotics.

• Flameless process.

• Heating is limited to the specific area.

2021年11月13日星期六

Annealing Titanium Fasteners With Induction

Annealing Titanium Fasteners With Induction Heater

Objective Heating a titanium fastener to 1100-1450ºF (593-788ºC) for an annealing process.

Material 0.06” (1.5mm) high zone on a titanium fastener measuring 0.163-0.375” (4.14-9.52mm) in diameter and 0.5-3.0” (12.7- 76.2mm) in length

Temperature 1100-1450ºF (593-788ºC)

Frequency 150 kHz

Equipment •DW-UHF-20kW induction heating system, equipped with a remote workhead containing one 0.66μF capacitor.

• An induction heating coil designed and developed specifically for this application.

Process A three turn concentrator plate coil is used to heat the fastener for 0.2 seconds. This is an automated process that includes robotic placement of parts in the coil from a bowl fed track while Argon gas is flooded across the part to prevent oxidation. The parts are processed at a rate of 1000 parts per minute.

Results/Benefits Induction heating provides:

• Can be incorporated easily with pick and place robotics.

• Flameless process.

• Heating is limited to the specific area.

Temperature 1100-1450ºF (593-788ºC)

Frequency 150 kHz

Equipment •DW-UHF-20kW induction heating system, equipped with a remote workhead containing one 0.66μF capacitor.

• An induction heating coil designed and developed specifically for this application.

Process A three turn concentrator plate coil is used to heat the fastener for 0.2 seconds. This is an automated process that includes robotic placement of parts in the coil from a bowl fed track while Argon gas is flooded across the part to prevent oxidation. The parts are processed at a rate of 1000 parts per minute.

Results/Benefits Induction heating provides:

• Can be incorporated easily with pick and place robotics.

• Flameless process.

• Heating is limited to the specific area.

Temperature 1100-1450ºF (593-788ºC)

Frequency 150 kHz

Equipment •DW-UHF-20kW induction heating system, equipped with a remote workhead containing one 0.66μF capacitor.

• An induction heating coil designed and developed specifically for this application.

Process A three turn concentrator plate coil is used to heat the fastener for 0.2 seconds. This is an automated process that includes robotic placement of parts in the coil from a bowl fed track while Argon gas is flooded across the part to prevent oxidation. The parts are processed at a rate of 1000 parts per minute.

Results/Benefits Induction heating provides:

• Can be incorporated easily with pick and place robotics.

• Flameless process.

• Heating is limited to the specific area.

Temperature 1100-1450ºF (593-788ºC)

Frequency 150 kHz

Equipment •DW-UHF-20kW induction heating system, equipped with a remote workhead containing one 0.66μF capacitor.

• An induction heating coil designed and developed specifically for this application.

Process A three turn concentrator plate coil is used to heat the fastener for 0.2 seconds. This is an automated process that includes robotic placement of parts in the coil from a bowl fed track while Argon gas is flooded across the part to prevent oxidation. The parts are processed at a rate of 1000 parts per minute.

Results/Benefits Induction heating provides:

• Can be incorporated easily with pick and place robotics.

• Flameless process.

• Heating is limited to the specific area.

关注者

博客归档

-

▼

2021

(398)

-

▼

十一月

(190)

- high frequency induction soldering wire to connector

- Induction Melting Aluminum

- What Is Induction Heating Coil&Inductor?

- Induction Melting Copper

- Soldering Solar Panels With Induction

- Induction Melting Brass

- High frequency induction brazing steel tube to ste...

- Induction Melting Gold

- Induction Brazing Basics

- Induction Melting Silver

- Induction Brazing Carbide Tipping on Cutting Steel...

- Induction Melting Stainless Steel

- Induction Drying Grain with Induction Heating method

- Induction Heating Turbine Fan For Welding

- Induction Brazing Carbide to Steel

- Induction Heating Titanium Blade

- Induction Annealing Steel Wire

- Induction Heating Steel Rods

- Induction Heating Wires For Hot Heading

- Induction Heating Copper Wire for Stripping

- What is induction annealing?

- Induction Heat setting Nitinol

- Induction Brazing Aluminum Pipes

- Induction Heating Wire Stripping

- Induction Shrink Fitting Steel Tube

- Induction Heating System Topology Review

- Induction Heating the end of catalytic converter

- Induction Hardening Surface Process

- Induction Heating Aluminum Automotive Wheel Hub

- Induction heating of aluminium billets

- Induction heating of cylindrical nonmagnetic ingots

- Advantages of Induction Heating

- Induction Heating End of Rods,Billets,Bars

- Induction Brazing Principle-Theory

- induction heating graphite carbon

- Induction Brazing Carbide To Stainless Steel

- induction heating hot rolling

- Brazing Brass to Aluminum with Induction

- induction heating rivets

- Induction Brazing copper to copper pipes

- Induction heating springs of automotive

- Induction inline wire heating process

- Induction Heating Aluminum

- Induction forging and induction hot forming

- Induction Heating Steel Handle For Bending

- Brazing Copper Tube with Induction

- induction heating steel plate

- Induction Shrink Fitting Aluminum Pump Housing Part

- Induction Heating Inner of Steel Liners

- Induction Heating Theory PDF

- induction heating aluminium

- aluminum scrap melting induction furnace

- Induction Heating Sealing

- Brazing Copper Tube to Brass Fitting With Induction

- Induction Hardening

- Induction Shrink Fitting Steel Tube

- Induction Bending Pipe-Tube

- Induction Hardening Saw Blades

- Induction Soldering Cables to Terminals

- Induction Hardening Gears Teeth

- high frequency induction hardening camshafts process

- Induction Hardening Knife Blade

- Plastic Injection Molding with Induction Heating

- Hardening Stainless Steel Knife Blades With Induction

- Induction Heating Automotive Motor

- Induction Hardening Cast Iron

- Induction Soldering Cables to Terminals

- Induction Hot Forming Titanium Rod

- Brazing Copper Assemblies With Induction

- Induction Forging

- induction heating medical and dental applications

- Induction Forging Steel Strip

- RPR Induction Stripping-Induction Rust & Paint Coa...

- Induction Forging Steel Rod End

- Brazing Wire to Copper Bar With Induction

- Induction Forging Titanium Rods

- Induction Brazing Steel Tips

- Induction Hot Forming Stainless Steel Tape

- PDF of Induction Heating Principle and Applicatons

- Induction Forging Billets

- Magnetic Induction Heater Manufacturer

- Induction Brazing

- Induction Annealing Stainless Steel Tubes

- Induction Brazing Stainless Steel Tubes

- induction heating nanoparticle solution

- Induction Brazing Stainless Steel To Brass

- Induction Brazing copper wire to copper cylinder

- Induction Brazing Copper Tube

- Induction Brazing Copper Assembly

- Induction Hot Forming Steel Pipe

- Induction Brazing Stainless Steel Tools

- Handheld Induction Brazing Copper Tubing and Fitting

- Induction Brazing Copper

- Induction Annealing Stainless Steel Tubes

- Induction Brazing Copper Billets

- Automatic Induction Forging Video

- Brazing Diamond Tools With Induction

- Technology of Induction Forming Steel Plate

- Induction Brazing Shaft

- Induction Hardening Steel Part with High Frequency...

-

▼

十一月

(190)

我的简介

- HLQ induction heating machine

- HLQ induction heating machine manufacturer provides the service of induction brazing,melting,hot forming,hardening surface,annealing,shrink fitting,PWHT,etc.