Annealing Brass Tubing,Copper Tube-Pipe With Induction Heating System

Objective Annealing brass and bronze tubing for bending in a mandrel bender to form handrails

Material • Brass tubes 1.5” (38.1mm) and 2” (50.8mm) diameter with 0.065” (1.65mm) wall thickness

• Bronze tubes 1.5” (38.1mm) and 2” (50.8mm) diameter with 0.100” (2.54mm) wall thickness

Temperature 1000 ºF (538 ºC)

Frequency 300 kHz

Equipment • DW-UHF-6kW induction heating system, equipped with a remote workhead containing two 0.5μF capacitors for a total of 0.25μF

• An induction heating coil designed and developed specifically for this application.

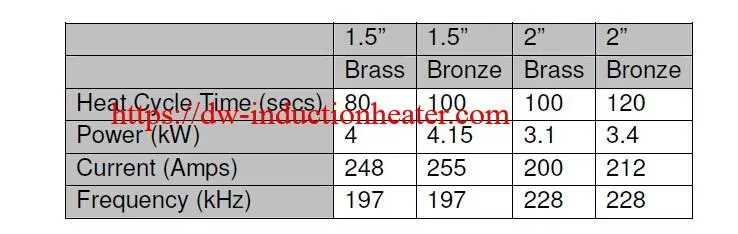

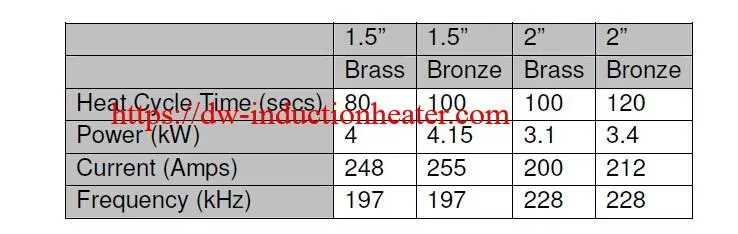

Process A twelve turn helical coil is used to heat an 8” (20.3cm) area 3” (7.6cm) above the end of the tube. Each of the four tubes require a different heat cycle and time to reach the required

temperature. Please see the chart below for each tube. 1.5” 1.5” 2” 2”

Results/Benefits Induction heating provides:

• High efficiency, low energy costs

• Precise and controllable placement of heat

• Hands-free heating that involves no operator skill for manufacturing

• Even distribution of heating, eliminating fractures during bending

• An induction heating coil designed and developed specifically for this application.

Process A twelve turn helical coil is used to heat an 8” (20.3cm) area 3” (7.6cm) above the end of the tube. Each of the four tubes require a different heat cycle and time to reach the required

temperature. Please see the chart below for each tube. 1.5” 1.5” 2” 2”

• An induction heating coil designed and developed specifically for this application.

Process A twelve turn helical coil is used to heat an 8” (20.3cm) area 3” (7.6cm) above the end of the tube. Each of the four tubes require a different heat cycle and time to reach the required

temperature. Please see the chart below for each tube. 1.5” 1.5” 2” 2”

Results/Benefits Induction heating provides:

• High efficiency, low energy costs

• Precise and controllable placement of heat

• Hands-free heating that involves no operator skill for manufacturing

• Even distribution of heating, eliminating fractures during bending

Results/Benefits Induction heating provides:

• High efficiency, low energy costs

• Precise and controllable placement of heat

• Hands-free heating that involves no operator skill for manufacturing

• Even distribution of heating, eliminating fractures during bending