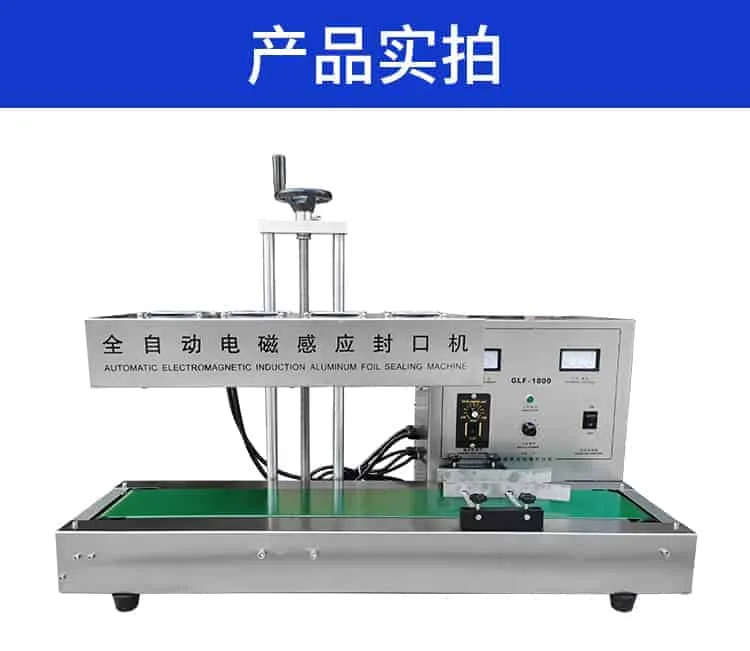

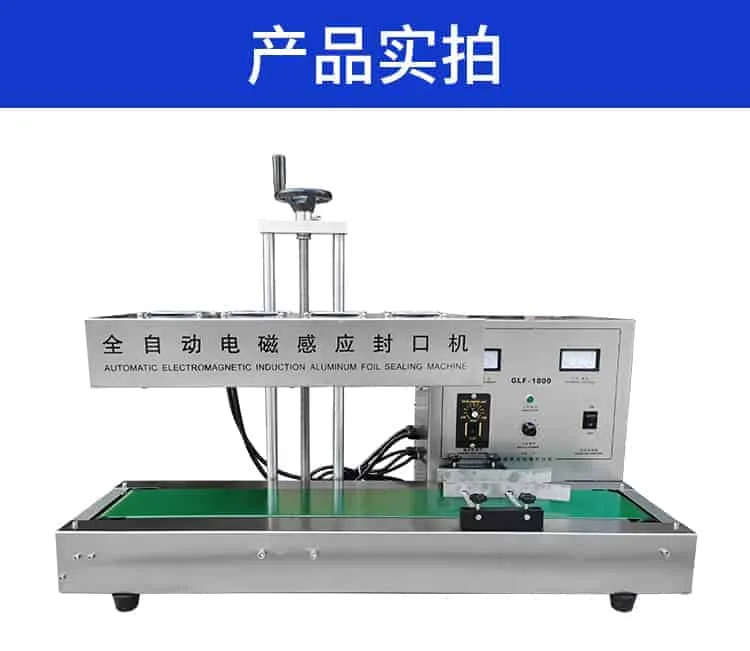

Aluminum Foil Sealing Machine with Induction Heating

What is “Induction aluminum foil sealing machine”?

Induction Aluminum Foil Sealing Machine is used for PP, PE, PET, PS, ABS, HDPE,LDPE and glass bottles, which utilizes electromagnetic principle to produce instant high heat to melt aluminum foil that then adheres to the opening of the bottles, reaching the aim of wet-proof, leakage-proof, mildew-proof and extending preservation time.

A common type of inner seal is a 2 pieces inner seal which leaves a secondary seal inside the caps once the induction seal has been removed. This is commonly used where issues of leakage are a concern. Another option is the single piece inner seal where once the induction seal is removed there is no liner left in the closure. You can also choose from seals that have a pulltab or ones that have a peelable seal leaving no residue on the bottle. You must be certain that the liner is compatible with the bottle material.

| Model |

2500W |

1800W |

1300W |

| Product Material |

Stainless Steel |

| Sealing Diameter |

60-180mm |

50-120mm |

15-60mm |

| Sealing Speed |

20-300 bottles/min |

| Transfer Speed |

0-12.5m/min |

| Sealing Height |

20-280mm |

20-180mm |

| Max Power |

2500W |

1800W |

1300W |

| Input Voltage |

Single phase,220V,50/60Hz |

| Applicable material |

PP, PE, PET, PS, ABS, HDPE,LDPE and glass bottles, Plastic bottle mouth aluminum foil film |

| Dimension(L*W*H): |

1005*440*390mm |

970*515*475mm |

| Weight |

72kg |

51kg |

38kg |

What is Induction Sealing?

Induction sealing is a non-contact method of bonding materials made from thermoplastics through electromagnetic induction which generates eddy currents to heat the materials. In the packaging industry, this process is used to hermetically seal a container cap having a foil laminate sealable by heat. In the case of our Aluminum Foil Induction Sealer Equipment, the foil laminate is an aluminum heat induction liner.

These packaging machines are used to hermetically seal glass and plastic containers via induction sealing to extend product shelf life, prevent leaks, and most especially to provide tamper-evident seals. Aluminum foil induction can seamer machines are available in electrically-powered, handheld, and manual designs for sealing various closure sizes.

What is an Aluminum Heat Induction Liner?

You’ve seen these things covering bottle and jar containers when you open a packaged product such as peanut butter or bottled medicines. An aluminum heat induction liner is a silver foil at the opening of a container that proves that the packaged product is tamper-evident. They require an aluminum foil induction can sealing equipment to properly seal these liners to the can.

Moreover, a typical aluminum heat induction liner inside a cap is a multi-layered seal made up of the following strategically situated and designed layers:

- A pulp paperboard layer

- A wax layer

- An aluminum foil layer

- A polymer layer

The topmost layer, which is the pulp paperboard layer, nests against the lid’s inside part and is spot-glued to it. Followed by a layer of wax used to bind the pulp paperboard layer to the third layer, the aluminum foil, which is the layer that adheres to the container. The last layer at the bottom is the polymer layer which looks like a plastic film.

These four layers work together in order to achieve the necessary dynamics for a successful induction process to produce an airtight seal.

Induction Sealing Applications

HLQ

aluminum foil induction sealing machines for screw caps are ideal for sealing food, beverages, medical products, and cosmetics among others in various bottle shapes, such as round and square bottles, made from plastic.

Furthermore, below are the various industries and products that LPE can seaming machines can handle.

These packaging machines are used to hermetically seal glass and plastic containers via induction sealing to extend product shelf life, prevent leaks, and most especially to provide tamper-evident seals. Aluminum foil induction can seamer machines are available in electrically-powered, handheld, and manual designs for sealing various closure sizes.

These packaging machines are used to hermetically seal glass and plastic containers via induction sealing to extend product shelf life, prevent leaks, and most especially to provide tamper-evident seals. Aluminum foil induction can seamer machines are available in electrically-powered, handheld, and manual designs for sealing various closure sizes.

Furthermore, below are the various industries and products that LPE can seaming machines can handle.

Furthermore, below are the various industries and products that LPE can seaming machines can handle.

Furthermore, below are the various industries and products that LPE can seaming machines can handle.

Furthermore, below are the various industries and products that LPE can seaming machines can handle.