2023年8月1日星期二

Induction Heat Setting

Induction Heat Setting A Shape Memory Alloy With IGBT Induction Heater

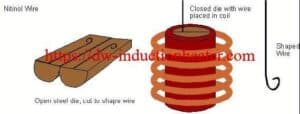

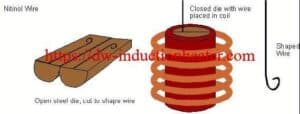

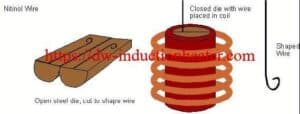

Objective Heat a steel die to 975°F (523.8ºC) to set (cure) a shape memory alloy in the correct position.

Material Nitinol wire, 2” (50.8mm) diameter tapered steel die, steel tube to house the die, instant adhesive

Temperature 975°F(523.8ºC)

Frequency 131kHz

Equipment • DW-UHF-6kW induction heating system equipped with a remote workhead containing one 1.0 μF capacitor

• An induction heating coil designed and developed specifically for this application.

Process A five turn helical coil is used to heat the steel die. The Nitinol wire is set into the die and tacked into place using instant adhesive. The die is placed inside a larger steel tube. The die cure is heated to 945ºF (507.2ºC) in 75 seconds. Successful heat setting of the Nitinol wire is achieved in 15 seconds.

Results/Benefits Induction heating provides:

• Fast, accurate, repeatable heating

• Heat precisely delivered only to where it is needed

关注者

博客归档

-

▼

2023

(1696)

-

▼

八月

(129)

- Induction Brazing Brass Faucet

- Aluminum Billet Heating Furnace

- Induction Preheat Welding Systems

- Induction Brazing Stainless Steel

- Billet Heating Furnace with Induction Heating

- induction brazing steel carbide cap to shaft

- Induction Soldering Cable to Metallic Plate

- Induction Brazing Principle-Theory

- Induction Hardening Inner

- aluminum scrap melting induction furnace

- Induction Brazing Steel Tips

- Aluminum Scrap Melting Recycling Induction Furnace

- Induction Brazing Carbide Tipping on Cutting Steel...

- induction hardening steel handheld stamps

- Melting Aluminum Tilting Crucible Induction Furnace

- ultrasonic welding fabric machine for bonding nonw...

- Tilting Crucible Melting Induction Furnace

- Ultrasonic Plastic Welding Machine For Bonding The...

- Electromagnetic Induction Steam Generator

- Why Choose Induction Heating and what are its adva...

- Induction Hardening Surface Process

- How to design induction heating coil

- Induction annealing copper wires

- Induction Preheat Welding Systems

- Induction forging and induction hot forming

- Induction Soldering Wire To Aluminum Lug

- Magnetic Induction Heating Boiler

- portable ultrasonic mask welding machine for weldi...

- Induction Soldering Electrical Circuits

- Induction Heating Basic

- Induction Wire and Cable Heating

- Induction annealing stainless steel wire

- Induction Soldering Stainless Steel Tubes to Brass...

- Induction Heating Basic

- Induction Annealing Copper Tubes

- Brazing stainless steel with induction

- Induction Shrink Fitting Aluminum Pump Housing Part

- Induction Heating Steel Mold

- Soldering Steel To Brass With Induction Heater

- Induction Brazing Aluminum to Aluminum Tube

- Induction Brazing Copper Tube of Heat Exchanger

- How Induction Heating works?

- induction brazing stainless steel to steel

- Induction Brazing Carbide Onto Steel Part

- Small High Frequency Induction Melting Furnace

- Efficient and Versatile Induction Heating Coils fo...

- Small High Frequency Induction Melting Furnace

- handbook of induction heating eddy current

- Efficient and Versatile Induction Heating Coils fo...

- Efficient and Versatile Induction Heating Coils fo...

- Induction Soldering Brass Tube-Pipe

- RPR Induction Stripping-Induction Rust & Paint Coa...

- Heating Shrink Fitting Camshaft Gear

- Handheld Brazing Stainless Steel Tube

- induction brazing copper and brass rods

- High frequency induction brazing steel tube to ste...

- Handheld Induction Brazing Copper Tubing and Fitting

- induction brazing brass pipe to brass part

- Induction Brazing Copper Tube For Refrigeration

- Induction annealing stainless steel wire

- Brazing Stainless Steel To Copper With Induction

- Induction Brazing Aluminum Tube T Joints

- Induction Handheld Brazing Copper To Steel Tube

- Induction Soldering Process Video

- Induction Brazing Aluminum to Aluminum Tube

- induction brazing copper and brass rods

- High Frequency Brazing Stainless Steel Fittings

- Induction Hot Forming Steel Pipe

- Induction Brazing Heating Exchanger Copper Pipes

- Induction Brazing Steel Parts to Tungsten Carbide ...

- what is induction forging?

- High Frequency Induction Brazing Copper Wire

- Small High Frequency Induction Melting Furnace

- Induction Soldering Copper Wire Connectors

- Induction inline wire heating process

- Induction Soldering Brass Assembly

- induction heating stainless steel wire cable

- Brazing Carbide To Steel With Induction

- Induction Hardening Steel Part with High Frequency...

- Induction Brazing Carbide To Steel

- high frequency induction hardening camshafts process

- Aluminium Scraps Recycling Melting and Process

- Shrink Fittting Part Removal application with Indu...

- Why Choose Induction Heating and what are its adva...

- induction soldering copper tubing to brass valves

- Induction Soldering Wire To Aluminum Lug

- Induction Soldering Brass Corner Joint

- Induction Shrink Fit Aluminum Shaft

- Induction Soldering Copper Wire Connectors

- high frequency induction soldering wire to connector

- Brazing Automotive Parts With Induction

- Induction Soldering Copper Pipes to PCB Board

- Brazing Golf Ball With Induction

- Induction Soldering Stainless Steel Tubes to Brass...

- induction brazing steel tube to copper tube

- Brazing Aluminum to Copper Tubes with Induction

- Induction Soldering Wire To Aluminum Lug

- Brazing Joining Copper Connectors With Induction

- high frequency induction soldering wire to connector

- Induction Heating Steel Mold

-

▼

八月

(129)

我的简介

- HLQ induction heating machine

- HLQ induction heating machine manufacturer provides the service of induction brazing,melting,hot forming,hardening surface,annealing,shrink fitting,PWHT,etc.