2022年3月21日星期一

induction heating graphite susceptor

Induction heating graphite susceptor for glass reflow for X-ray tubes

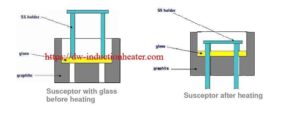

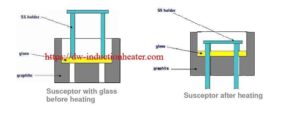

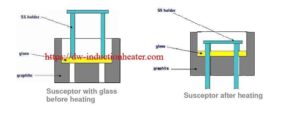

Objective Heat graphite susceptor for glass reflow in the manufacturing of x-ray tubes

Material Glass disc 0.98 x 0.12 “ (25 x 3mm), graphite susceptor, stainless steel holder, Glass bell jar 5.9” (150mm) OD

Temperature 1742 ºF (950º C)

Frequency 80 kHz

Equipment • DW-HF-25kW induction heating system, equipped with a remote workhead containing eight 0.3 μF capacitors for a total of 2.4 μF

• An induction heating coil designed and developed specifically for this application.

Process A two turn helical coil is used for heating. Six graphite susceptors are placed in the nitrogen atmosphere with glass discs and a stainless steel holder. In 32 seconds the required temperature of 1742 ºF (950º C) is reached causing the glass to reflow & the stainless steel holder to melt through the glass.

Results/Benefits Induction heating provides:

• Increased production, customer currently heating 4 susceptors

• 50% lower energy consummation

• Even distribution of heating

关注者

博客归档

-

▼

2022

(1729)

-

▼

三月

(100)

- Brazing stainless steel with induction

- Induction Soldering Stainless Steel Tubes to Brass...

- Electromagnetic Induction Heating Steam Generators

- Induction Aluminum Brazing Process

- Electromagnetic Induction Heating Steam Generators

- Induction Heating Steel Mold

- Induction Soldering Brass Tube-Pipe

- Brazing Copper to Brass Pipe With Induction

- induction surface hardening steel screws

- Induction Catheter Tipping Heating

- Induction Preheating Welding Steel Pipe

- induction brazing automotive copper heating exchan...

- Brazing Aluminum Pipes Assembly With Induction

- What is induction hardening?

- Induction Heating Wires For Hot Heading

- Shrink Fitting Assemble Connecting Rods

- Induction Preheating Welding Steel Pipe

- Induction Annealing Copper Tubes

- Induction Brazing Heating Exchanger Copper Pipes

- Brazing Joining Copper Connectors With Induction

- Brazing Copper Bars with Induction

- Induction Drying Grain with Induction Heating method

- Brazing Brass Pipe With Induction

- induction heating reactor tank-vessels

- induction soldering fiber optic cable

- Magnetic Induction Heating Boiler

- Brazing carbide shaft with induction

- Brazing carbide shaft with induction

- Induction Hardening and tempering

- Induction Soldering Coaxial Cable

- Induction Soldering Copper Pipes to PCB Board

- Induction Annealing Aluminum

- induction hot forming and forging process

- Ultrasonic Plastic Welding Machine For Bonding The...

- induction heating graphite susceptor

- Brazing Copper Tube to Brass Fitting With Induction

- Induction Curing Heating of Organic Coating

- Induction forging and induction hot forming

- induction curing

- Brazing Carbide-Steel Tool with Induction

- Induction Brazing Heating Exchanger Copper Pipes

- Research and Design on IGBT Induction Heating Powe...

- Brazing Aluminum Tubes with Induction Heating

- Induction Brazing Carbide Onto Steel Part

- Induction Soldering Copper Wire Connectors

- Induction Soldering Stainless Steel To Wire

- Annealing Saw Blades with Induction

- Brazing Carbide Tips To Steel With Induction

- induction Brazing copper rods to brass strips

- Aluminum Scrap Melting Recycling Induction Furnace

- Induction Soldering Coaxial Cable to Connector Ring

- induction heating for drying food processing industry

- Induction Brazing Copper To Copper Parts

- Induction Heating Bolts

- Small High Frequency Induction Melting Furnace

- induction heating stainless steel wire cable

- how does induction heating work?

- Induction Hardening and tempering

- Brazing Golf Ball With Induction

- how does induction heating work?

- Brazing Stainless Steel To Copper With Induction

- Induction Heat Treating Surface Process

- Brazing Brass Fittings With Induction

- Induction Tempering Spring

- Induction Heating Aluminum Catheter Tipping

- induction heating nanoparticle solution

- What Is Induction Heating?

- Brazing Carbide Tool Tips With Induction

- Brazing Stainless Steel To Copper With Induction

- Induction Fluid Pipeline heating system

- Billet Heating Furnace with Induction Heating

- Small High Frequency Induction Melting Furnace

- Brazing Brass Pipe With Induction

- Induction Soldering Brass To Copper

- Brazing Aluminum Pipes Assembly With Induction

- Induction Soldering Brass Tube-Pipe

- Heating Aluminum Foil For Cap Sealing

- how does induction heating work?

- induction heating stress relieving

- Induction Brazing Aluminum to Aluminum Tube

- Soldering Steel To Brass With Induction Heater

- Brazing Steel To Steel Pipe With Induction

- Induction Susceptor Heating

- Induction Brazing Copper T Pipe With Induction Hea...

- Shrink Fitting Assemble Connecting Rods

- Magnetic Induction Heater Manufacturer

- Induction Aluminum Brazing with Computer Assisted

- Induction Hot Plate

- Billet Heating Furnace with Induction Heating

- induction heating for surface quenching of steel

- induction heating steel cable for cutting

- Electromagnetic Induction Heater

- Electromagnetic Induction Heater

- Induction Brazing Copper Assembly

- Brazing Joining Copper Connectors With Induction

- Induction Brazing Steel Wire

- Induction Heating Magnetic Iron Oxide

- Induction Soldering Steel Cover

- Induction Heating Chemical Reactor

- Induction Annealing Aluminum PIpe

-

▼

三月

(100)

我的简介

- HLQ induction heating machine

- HLQ induction heating machine manufacturer provides the service of induction brazing,melting,hot forming,hardening surface,annealing,shrink fitting,PWHT,etc.