How Induction Susceptor Heating Works?

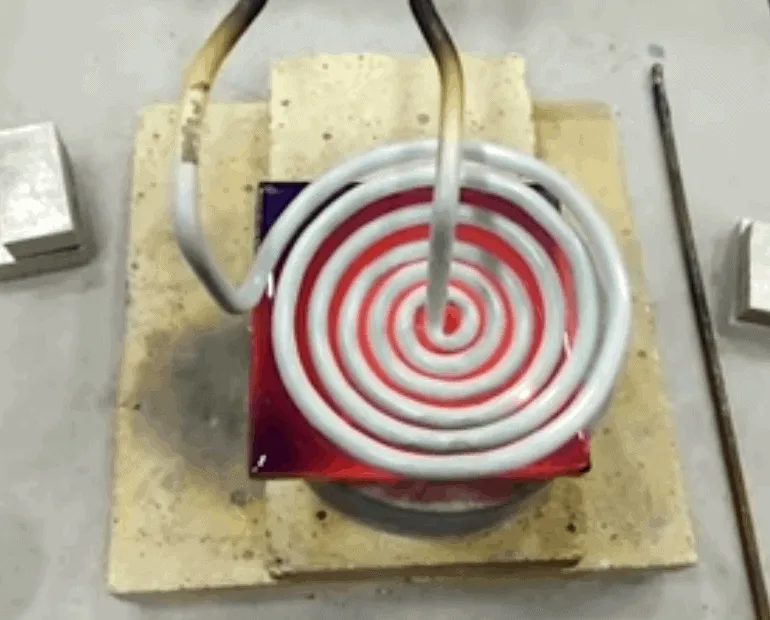

A susceptor is used for the

induction heating of non-conductive materials such as ceramics and polymers. The susceptor is heated by an induction heating system, where conduction transfers heat to the work material. Susceptors are often made out of silicon carbide, molybdenum, graphite, stainless steels and a number of other conductive materials.

With susceptor heating, we use induction to heat a metal conductive susceptor, which then heats a secondary material either through direct contact conduction or radiation.

What is Induction Susceptor Heating?

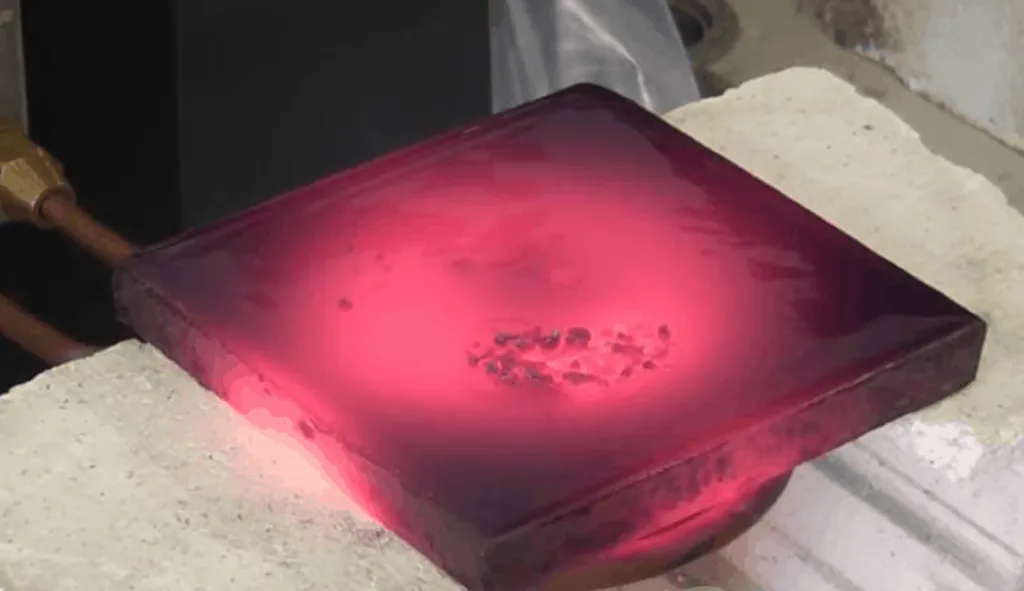

Susceptor heating by Induction has been extensively applied to processes where the material to be heated is not electrically conductive or not easily heated evenly with induction heating. Both metallic and non-metallic parts may be heated indirectly with the use of a susceptor, heated by induction. Susceptors may be in contact with or separated from the part or material to be heated. When in contact heating is via conduction, when separated heating is by radiation.

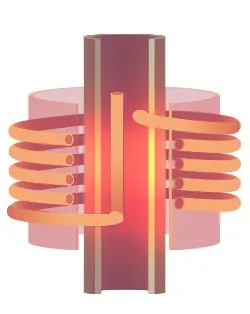

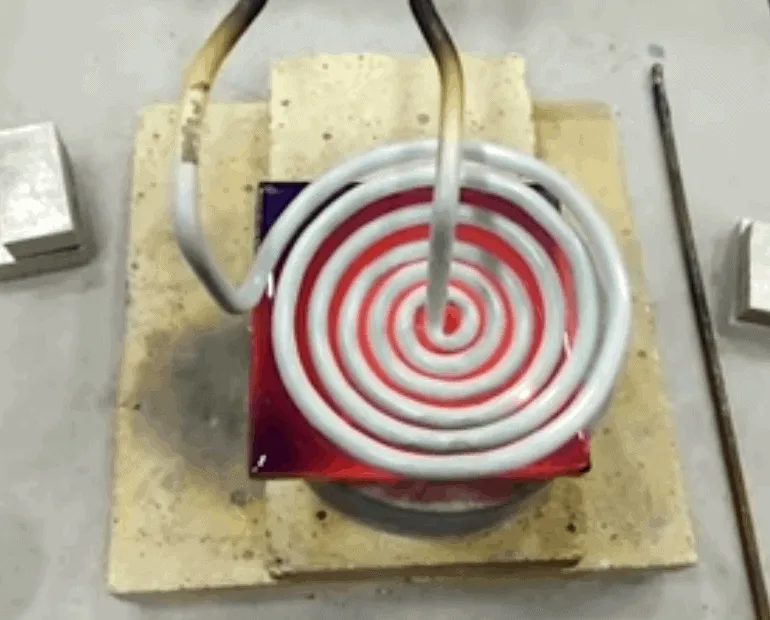

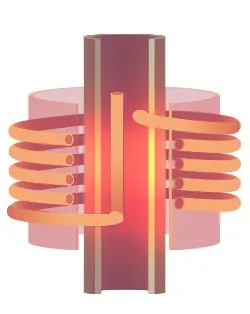

The term ‘susceptor’ as used in induction heating denotes an electrically conductive material placed between the induction heating coil and the material to be heated such as a workpiece, either a solid, a slurry, a liquid, a gas, or some combination of the foregoing. In its simplest form, an Induction Susceptor Heater may be a metal tube interposed between the coil and the material to be heated. Such a susceptor is readily heated by the electromagnetic field established by the induction coil so that the part is heated primarily by radiation or conduction from the heated susceptor. Use of a susceptor provides an effective means for heating non-conductive materials like ceramics, glass, plastics, semiconductors, organic and non-organic chemicals, foods, beverages by taking advantage of the control precision, efficiency, rapid ramp-up, and reliability benefits of using an induction heating generator/power supply. HLQ designs and supplies

induction susceptor heating equipment from simple tubes through to heated conveyors, augers, and other complicated structures.

Susceptors may be designed and employed to protect/shield areas of a part that are not to be subjected to an induction field thus controlling the heat pattern obtained. In some cases, these are referred to as diverters or shields. In such instances, the susceptor covers the portion of the part electromagnetically shielding it. If a susceptor does not completely encircle the part, heating will take place simultaneously by direct induction heating in the unshielded zones as well as by radiation and conduction from the susceptor. In many cases shielding susceptors are constructed of water-cooled copper where the shielded zones of the part are not to be heated at all.

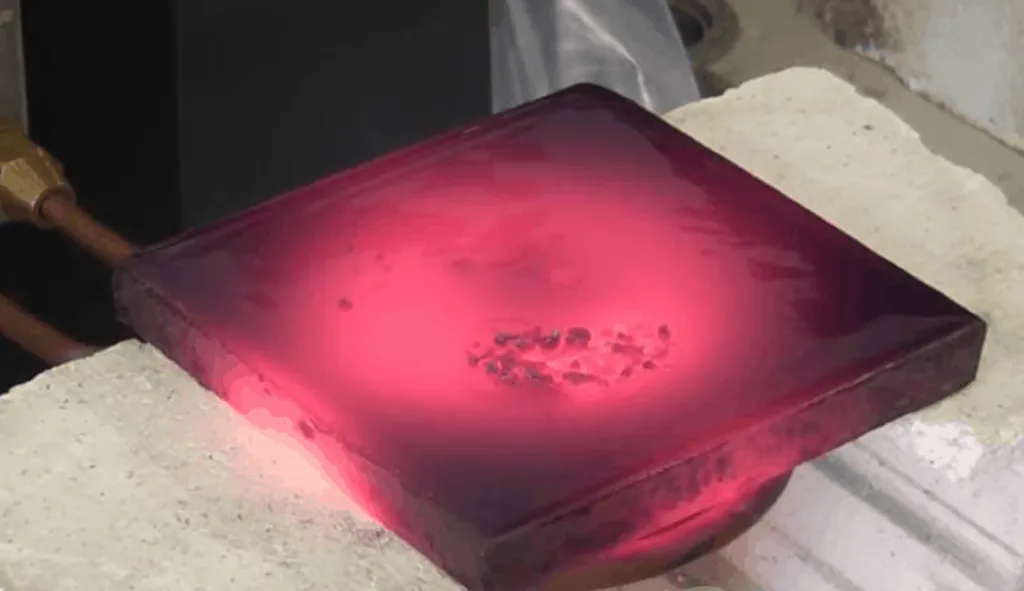

Fundamentally, susceptor heating using an

induction heating source is simply radiation and/or conduction heating. However, many features make it highly adaptable. Firstly, the susceptor is heated electromagnetically, permitting heating through quartz, glass, or other magnetically transparent chambers for atmosphere containment and control. Secondly, a thin susceptor acts as a radiation source that can be rapidly heated and cooled if desired, creating a heat source that can change temperature very rapidly. Induction heating that susceptor allows for higher reliability due to the fact that the high-temperature susceptor does not have to be connected to a high current conductor to impart the energy required for heating. The susceptor may be of any size. In parts with complex geometry, a susceptor improves the uniformity of heating, as compared to direct induction heating. Susceptors allow for very thin materials such as steel strips or wires to be heated to elevated temperatures using more economical low and medium magnetic field frequencies. When considering a susceptor heating design there are a number of factors that go into selecting the appropriate susceptor material, these include reactivity with the environment that the susceptor is in contact with. Choosing the right material leads to a reliable system, choosing the wrong materials can lead to contamination and low-reliability performance.

Induction Susceptor Heating Applications

Susceptors make

induction heating applicable for heating all non-metallic and metallic materials, allowing induction heating to become an important tool in the production of Foods and Beverages, Chemicals, Electronics, Glass, Plastics, Rubber, Construction, Consumer Medical, and industrial products.

https://dw-inductionheater.com/induction-susceptor-heating.html?feed_id=218311&_unique_id=64ac0455c1d76

https://dw-inductionheater.com/induction-susceptor-heating.html?feed_id=218311&_unique_id=64ac0455c1d76

The term ‘susceptor’ as used in induction heating denotes an electrically conductive material placed between the induction heating coil and the material to be heated such as a workpiece, either a solid, a slurry, a liquid, a gas, or some combination of the foregoing. In its simplest form, an Induction Susceptor Heater may be a metal tube interposed between the coil and the material to be heated. Such a susceptor is readily heated by the electromagnetic field established by the induction coil so that the part is heated primarily by radiation or conduction from the heated susceptor. Use of a susceptor provides an effective means for heating non-conductive materials like ceramics, glass, plastics, semiconductors, organic and non-organic chemicals, foods, beverages by taking advantage of the control precision, efficiency, rapid ramp-up, and reliability benefits of using an induction heating generator/power supply. HLQ designs and supplies induction susceptor heating equipment from simple tubes through to heated conveyors, augers, and other complicated structures.

Susceptors may be designed and employed to protect/shield areas of a part that are not to be subjected to an induction field thus controlling the heat pattern obtained. In some cases, these are referred to as diverters or shields. In such instances, the susceptor covers the portion of the part electromagnetically shielding it. If a susceptor does not completely encircle the part, heating will take place simultaneously by direct induction heating in the unshielded zones as well as by radiation and conduction from the susceptor. In many cases shielding susceptors are constructed of water-cooled copper where the shielded zones of the part are not to be heated at all.

The term ‘susceptor’ as used in induction heating denotes an electrically conductive material placed between the induction heating coil and the material to be heated such as a workpiece, either a solid, a slurry, a liquid, a gas, or some combination of the foregoing. In its simplest form, an Induction Susceptor Heater may be a metal tube interposed between the coil and the material to be heated. Such a susceptor is readily heated by the electromagnetic field established by the induction coil so that the part is heated primarily by radiation or conduction from the heated susceptor. Use of a susceptor provides an effective means for heating non-conductive materials like ceramics, glass, plastics, semiconductors, organic and non-organic chemicals, foods, beverages by taking advantage of the control precision, efficiency, rapid ramp-up, and reliability benefits of using an induction heating generator/power supply. HLQ designs and supplies induction susceptor heating equipment from simple tubes through to heated conveyors, augers, and other complicated structures.

Susceptors may be designed and employed to protect/shield areas of a part that are not to be subjected to an induction field thus controlling the heat pattern obtained. In some cases, these are referred to as diverters or shields. In such instances, the susceptor covers the portion of the part electromagnetically shielding it. If a susceptor does not completely encircle the part, heating will take place simultaneously by direct induction heating in the unshielded zones as well as by radiation and conduction from the susceptor. In many cases shielding susceptors are constructed of water-cooled copper where the shielded zones of the part are not to be heated at all.

Fundamentally, susceptor heating using an induction heating source is simply radiation and/or conduction heating. However, many features make it highly adaptable. Firstly, the susceptor is heated electromagnetically, permitting heating through quartz, glass, or other magnetically transparent chambers for atmosphere containment and control. Secondly, a thin susceptor acts as a radiation source that can be rapidly heated and cooled if desired, creating a heat source that can change temperature very rapidly. Induction heating that susceptor allows for higher reliability due to the fact that the high-temperature susceptor does not have to be connected to a high current conductor to impart the energy required for heating. The susceptor may be of any size. In parts with complex geometry, a susceptor improves the uniformity of heating, as compared to direct induction heating. Susceptors allow for very thin materials such as steel strips or wires to be heated to elevated temperatures using more economical low and medium magnetic field frequencies. When considering a susceptor heating design there are a number of factors that go into selecting the appropriate susceptor material, these include reactivity with the environment that the susceptor is in contact with. Choosing the right material leads to a reliable system, choosing the wrong materials can lead to contamination and low-reliability performance.

Fundamentally, susceptor heating using an induction heating source is simply radiation and/or conduction heating. However, many features make it highly adaptable. Firstly, the susceptor is heated electromagnetically, permitting heating through quartz, glass, or other magnetically transparent chambers for atmosphere containment and control. Secondly, a thin susceptor acts as a radiation source that can be rapidly heated and cooled if desired, creating a heat source that can change temperature very rapidly. Induction heating that susceptor allows for higher reliability due to the fact that the high-temperature susceptor does not have to be connected to a high current conductor to impart the energy required for heating. The susceptor may be of any size. In parts with complex geometry, a susceptor improves the uniformity of heating, as compared to direct induction heating. Susceptors allow for very thin materials such as steel strips or wires to be heated to elevated temperatures using more economical low and medium magnetic field frequencies. When considering a susceptor heating design there are a number of factors that go into selecting the appropriate susceptor material, these include reactivity with the environment that the susceptor is in contact with. Choosing the right material leads to a reliable system, choosing the wrong materials can lead to contamination and low-reliability performance.

https://dw-inductionheater.com/induction-susceptor-heating.html?feed_id=218311&_unique_id=64ac0455c1d76

https://dw-inductionheater.com/induction-susceptor-heating.html?feed_id=218311&_unique_id=64ac0455c1d76