The Advantages of Using an Induction Drum Ore Drying Heater for Efficient Processing.

An

induction drum ore drying heater is a type of industrial induction heating equipment used to dry ore in mining operations. The system uses electromagnetic induction to generate heat inside a rotating drum, which contains the wet ore. The heat causes the moisture in the ore to evaporate, leaving behind a dry product that is easier to transport and process.

Ore drying is an essential process in the mining industry, as it is crucial for the extraction of minerals.

Traditional drying methods, such as using fossil fuels and hot air, can be costly and inefficient. This is where induction drum ore drying heaters come in handy. These innovative heaters use electromagnetic induction to generate heat, which can dry ore much more quickly and efficiently than traditional methods. In this article, we will discuss the advantages of using an induction drum ore drying heater. You will learn how it can help you to increase your processing efficiency, reduce your energy consumption, and save you money in the long run.

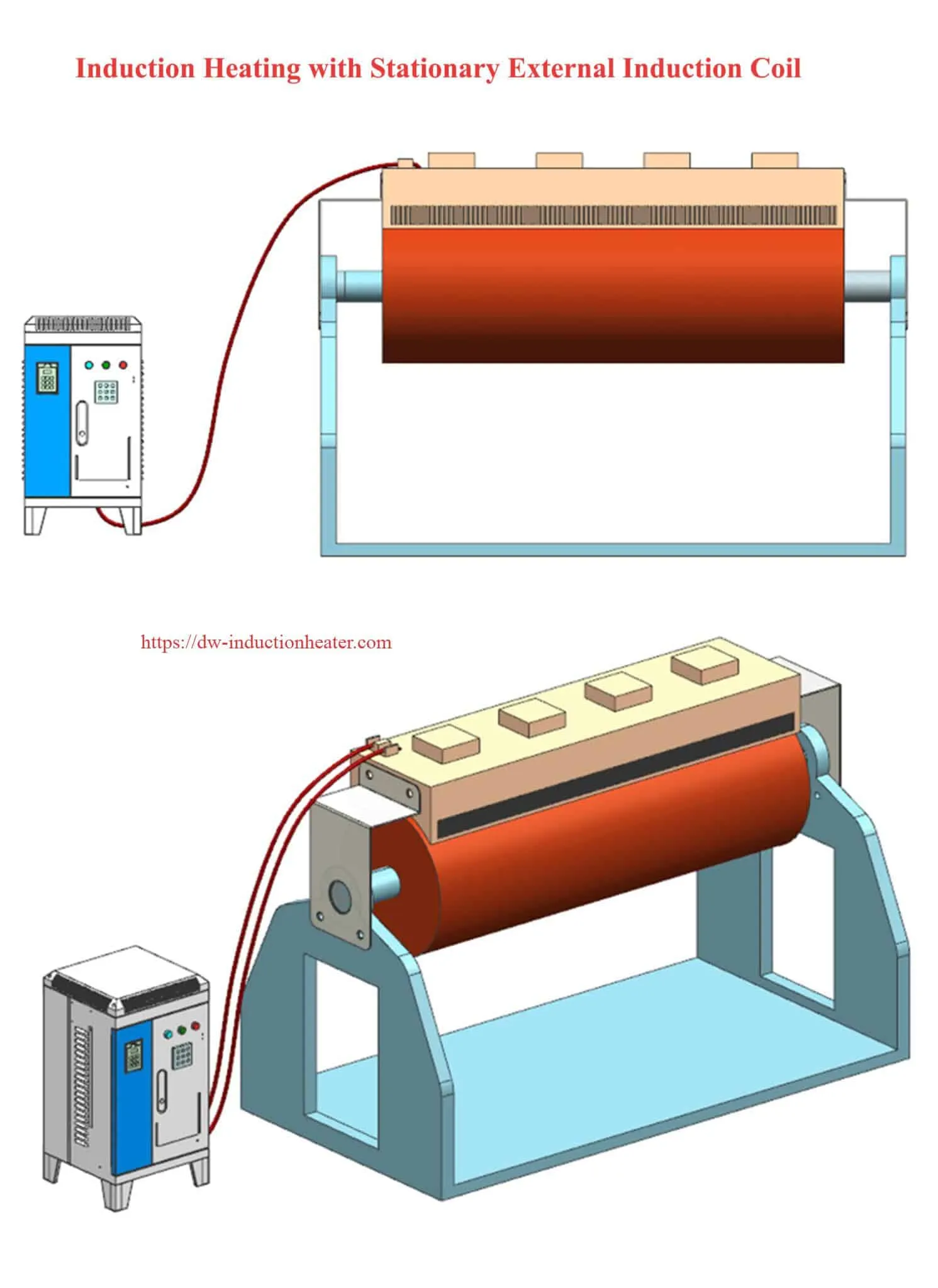

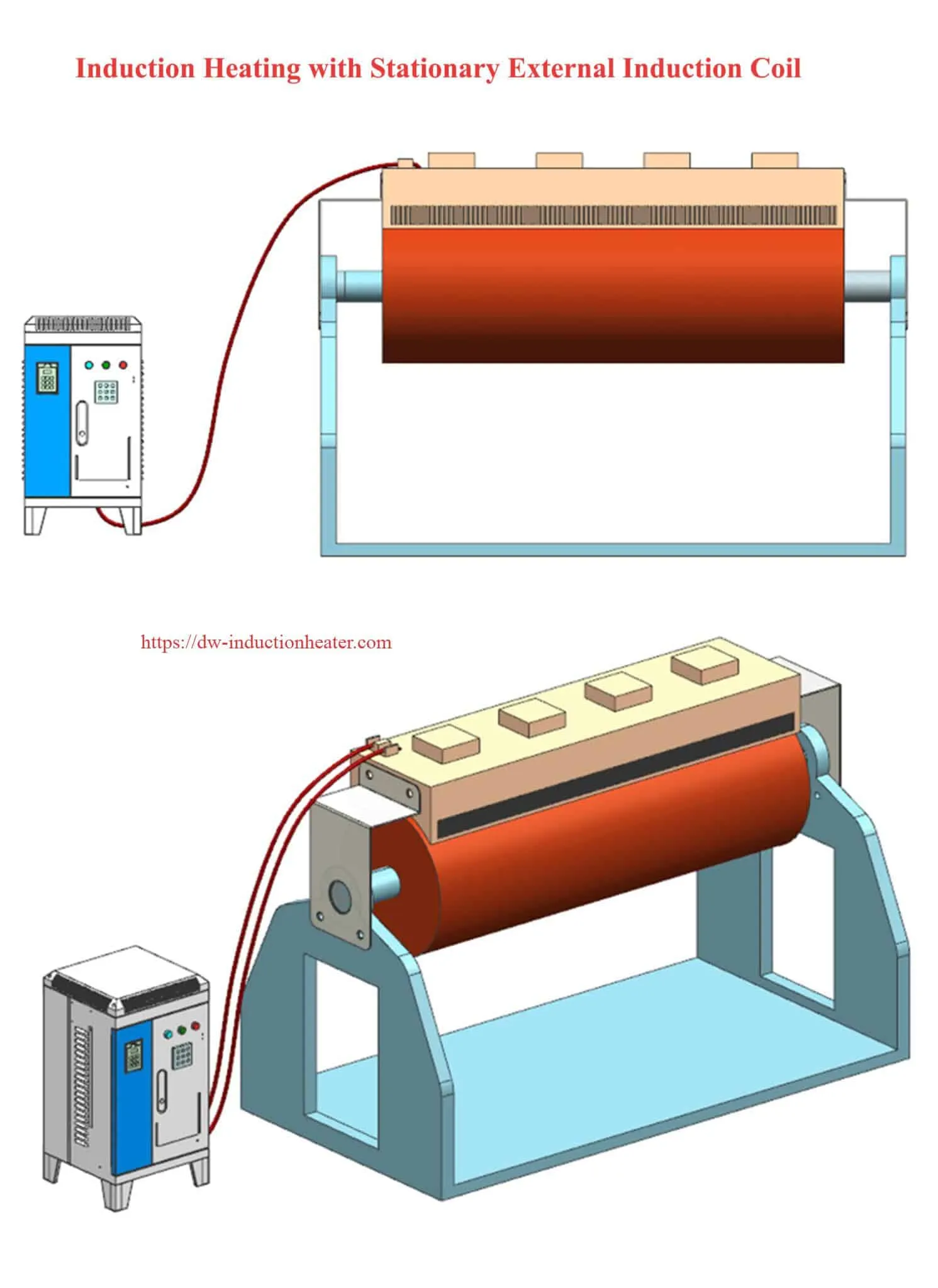

The induction drum ore drying heater consists of a specially designed drum that is made of steel or other heat-resistant materials. Inside the drum, a series of induction coils generate an electromagnetic field that heats the metal walls of the drum. As the drum rotates, the wet ore inside is exposed to the heat and begins to dry out.

The induction drum ore drying heater is an energy-efficient option for drying ore because it uses electromagnetic induction to generate heat, which is more efficient than traditional heating methods that rely on combustion. Additionally, the system is easy to control and can be adjusted to meet specific drying requirements.

1. What is an induction drum ore drying heater?

An induction drum ore drying heater is an advanced technology used in the process of drying ore. It uses electromagnetic induction to create heat directly within the ore, making the drying process more efficient and less time-consuming. This technology involves passing high-frequency alternating currents through copper coils that are located around the drum. When the alternating currents pass through the coils, they create a magnetic field that heats the drum and the ore inside. The heat generated by this process is uniform and can be controlled to produce the desired drying temperature. Unlike traditional drying methods, which require the use of fuel, the induction drum ore drying heater uses electricity, making it more eco-friendly and cost-effective. This innovative technology has proven to be extremely efficient and effective, reducing the drying time of ore significantly. Furthermore, using an induction drum ore drying heater for processing ore results in a higher quality product due to the uniformity of the drying process.

Technology Parameters:

| Items |

Unit |

Parameters Data |

| Output power |

kW |

20 |

30 |

40 |

60 |

80 |

120 |

160 |

| Current |

A |

30 |

40 |

60 |

90 |

120 |

180 |

240 |

| Input voltage/Frequency |

V/Hz |

3phases,380/50-60 (It can be customized) |

| Supply voltage |

V |

340-420 |

| Cross section area of power cable |

mm² |

≥10 |

≥16 |

≥16 |

≥25 |

≥35 |

≥70 |

≥95 |

| Heating efficiency |

% |

≥98 |

| Operating frequency range |

KHz |

5-30 |

| Thickness of insulation cotton |

mm |

20-25 |

| Inductance |

uH |

260-300 |

200-240 |

180-220 |

165-200 |

145-180 |

120-145 |

100-120 |

| Cross section area of heating wire |

mm² |

≥25 |

≥35 |

≥35 |

≥40 |

≥50 |

≥70 |

≥95 |

| Dimensions |

mm |

520*430*900 |

520*430*900 |

600*410*1200 |

| Power adjustment range |

% |

10-100 |

| Cooling method |

Air cooled / Water cooled |

| Weight |

Kg |

35 |

40 |

53 |

58 |

63 |

65 |

75 |

2. How does an induction drum ore drying heater work?

An induction drum ore drying heater is an efficient and effective way to process materials. The way it works is through the use of electromagnetic fields. When an alternating current is passed through a coil, an electromagnetic field is created. This field induces an electric current in the material being processed, causing it to heat up. The heat generated is used to dry the material, making it ready for further processing. This method is much more efficient than traditional heating methods, such as gas or electric heating, as it uses a fraction of the energy. The advantage of using an induction drum ore drying heater is that it can be used for a wide range of materials, including ceramics, metals, and ores. It is also environmentally friendly, as it does not produce any harmful emissions, making it a great choice for companies looking to reduce their carbon footprint. In addition, it is a safe and reliable method of processing materials, as there is no open flame or high temperatures involved. Overall, induction drum ore drying heaters are an excellent choice for companies looking to increase their processing efficiency while reducing their environmental impact.

3. Advantages of using an induction drum ore drying heater

An

induction drum ore drying heater is a type of heating system that uses electromagnetic induction to heat the metal drum. This method of heating has become increasingly popular in recent years due to the many advantages it offers over other heating methods. One of the main advantages of using an induction drum ore drying heater is that it is much more energy-efficient than traditional heating methods. This is because the heat is generated directly inside the drum, which reduces heat loss and increases efficiency. Another advantage of this method is that it helps to reduce the drying time of ore. The electromagnetic induction waves heat the drum evenly and efficiently, which in turn creates a much faster drying process. This leads to increased productivity and reduced energy costs. Additionally, this method of heating is much safer than traditional methods, as there is no open flame or hot surface that could cause a fire. Moreover, an induction drum ore drying heater is much easier to maintain and clean than other types of heating systems. It is a durable and reliable system that can withstand extreme temperatures and conditions, ensuring a long lifespan with minimal maintenance. Overall, using an induction drum ore drying heater is a smart choice for any industry looking for a more efficient, safe, and cost-effective heating solution.

4. Conclusion.

In conclusion, using an

induction drum ore drying heater can bring significant advantages to your processing facility. It can increase efficiency, reduce costs, and improve product quality. This type of equipment is designed to heat and dry bulk material quickly and evenly, resulting in a more uniform end product. The induction heating method is also more energy-efficient than traditional heating methods, saving you money on energy costs. Additionally, the lack of direct flame or hot air circulation in the induction heating process reduces the risk of fire and minimizes the environmental impact. Overall, investing in an induction drum ore drying heater is a wise decision for any processing facility looking to improve its operations and stay competitive in the market.

Ore drying is an essential process in the mining industry, as it is crucial for the extraction of minerals.

Ore drying is an essential process in the mining industry, as it is crucial for the extraction of minerals. Traditional drying methods, such as using fossil fuels and hot air, can be costly and inefficient. This is where induction drum ore drying heaters come in handy. These innovative heaters use electromagnetic induction to generate heat, which can dry ore much more quickly and efficiently than traditional methods. In this article, we will discuss the advantages of using an induction drum ore drying heater. You will learn how it can help you to increase your processing efficiency, reduce your energy consumption, and save you money in the long run.

The induction drum ore drying heater consists of a specially designed drum that is made of steel or other heat-resistant materials. Inside the drum, a series of induction coils generate an electromagnetic field that heats the metal walls of the drum. As the drum rotates, the wet ore inside is exposed to the heat and begins to dry out.

The induction drum ore drying heater is an energy-efficient option for drying ore because it uses electromagnetic induction to generate heat, which is more efficient than traditional heating methods that rely on combustion. Additionally, the system is easy to control and can be adjusted to meet specific drying requirements.

Traditional drying methods, such as using fossil fuels and hot air, can be costly and inefficient. This is where induction drum ore drying heaters come in handy. These innovative heaters use electromagnetic induction to generate heat, which can dry ore much more quickly and efficiently than traditional methods. In this article, we will discuss the advantages of using an induction drum ore drying heater. You will learn how it can help you to increase your processing efficiency, reduce your energy consumption, and save you money in the long run.

The induction drum ore drying heater consists of a specially designed drum that is made of steel or other heat-resistant materials. Inside the drum, a series of induction coils generate an electromagnetic field that heats the metal walls of the drum. As the drum rotates, the wet ore inside is exposed to the heat and begins to dry out.

The induction drum ore drying heater is an energy-efficient option for drying ore because it uses electromagnetic induction to generate heat, which is more efficient than traditional heating methods that rely on combustion. Additionally, the system is easy to control and can be adjusted to meet specific drying requirements.

Technology Parameters:

Technology Parameters: