One of the recent outstanding developments in the heat treating field has been the application of

induction heating to localized surface hardening. The advances made contingent with the application of high frequency current have been nothing short of phenomenal. Starting a comparatively short time ago as a long-sought-after method of hardening bearing surfaces on crankshafts (several million of these are in use setting all time service records), today finds this very selective surfacing hardening method producing hardened areas on a multiplicity of parts. Yet, in spite of its present day breadth of application, induction hardening is still in its infant stage. Its probable utilization for the heat treating and hardening of metals, heating for forging or brazing, or soldering of similar and dissimilar metals, is unpredictable.

Induction hardening results in the production of locally hardened steel objects with the desired degree of depth and hardness, essential metallurgical structure of core, demarcation zone, and hardened case, with a practical lack of distortion and no scale formation. It permits equipment design which warrants mechanization of the whole operation to fulfill production line requirements. Time cycles of only a few seconds are maintained by automatic regulation of power and split second heating and quenching intervals indispensable to the creation of facsimile results of exacting special fixations. Induction hardening equipment permits the user to surface harden only the requisite portion of most any steel object and thus maintain the original ductility and strength; to harden articles of intricate design which cannot be feasibly treated in any other way; to eliminate usual expensive pretreatment such as copper plating and carburizing, and costly subsequent straightening and cleaning operations; to cut down on material cost by having a wide selection of steels from which to choose; and to harden a fully-machined item without the necessity of any finishing operations.

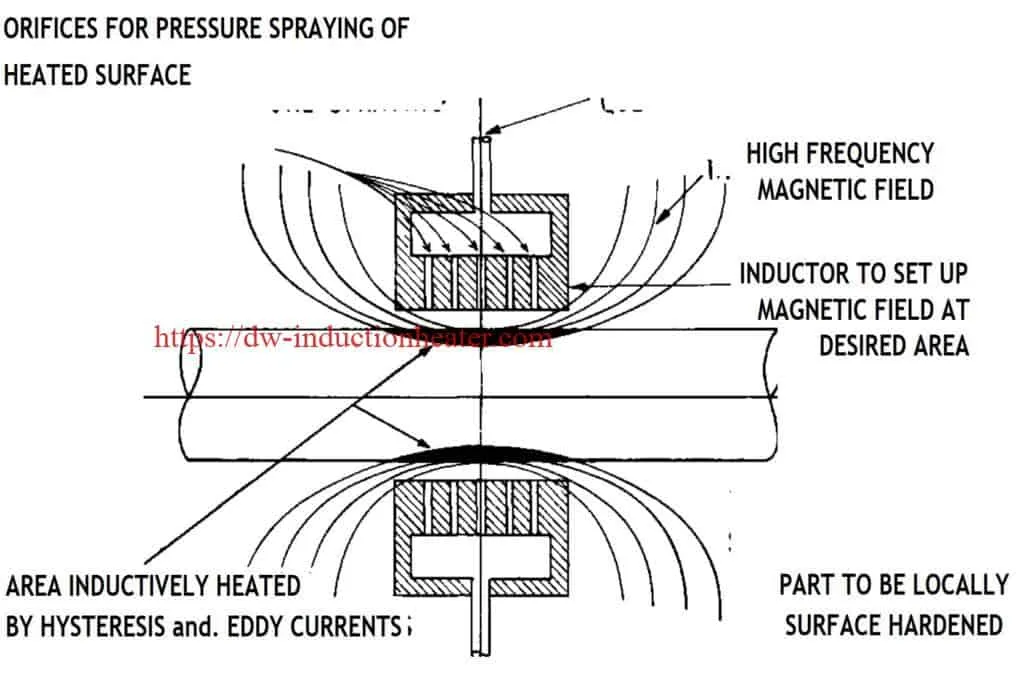

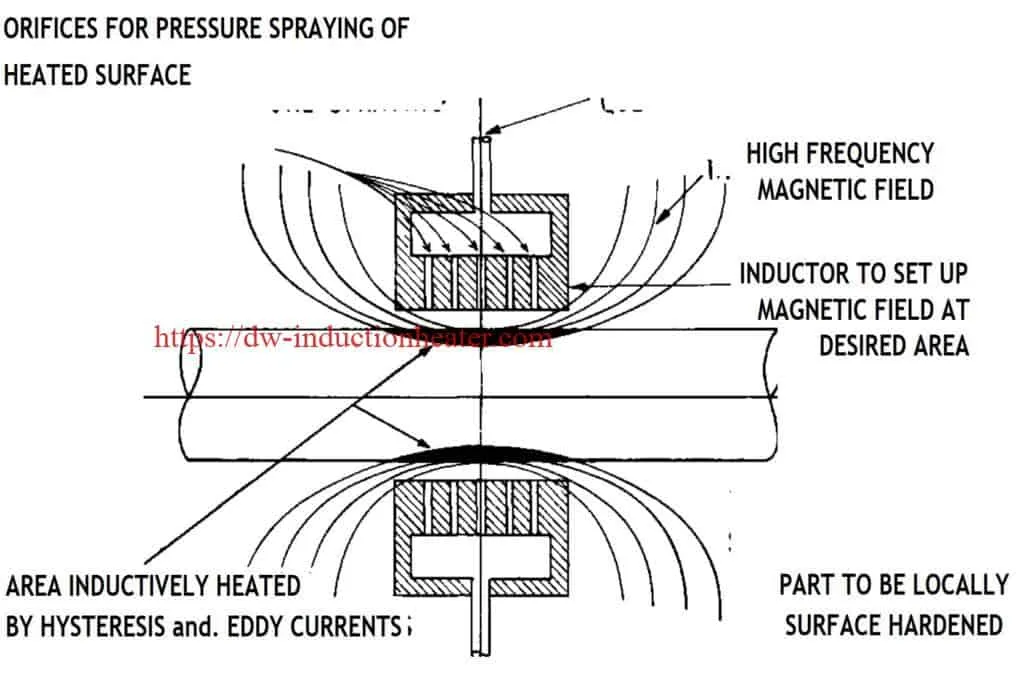

To the casual observer it would appear that induction hardening is possible as a result of some energy transformation occurring within an inductive region of copper. The copper carries an electrical current of high frequency and, within an interval of a few seconds, the surface of a piece of steel placed within this energized region is heated to its critical range and quenched to optimum hardness. To the manufacturer of equipment for this method of hardening it means the application of the phenomena of hysteresis, eddy currents, and skin effect to the effective production of localized surface hardening.

The heating is accomplished by use of high frequency currents. Specifically chosen frequencies from 2,000 to 10,000 cycles and upwards of 100,000 cycles are being used extensively at the present time. Current of this nature in flowing through an inductor produces a high-frequency magnetic field within the region of the inductor. When a magnetic material such as steel is placed within this field, there is a dissipation of energy in the steel which produces heat. The molecules within the steel attempt to align themselves with the polarity of this field, and with this changing thousands of times per second, an enormous amount of internal molecular friction is developed as a result of the natural tendency for the steel to resist changes. In this manner the electrical energy is transformed, through the medium of friction, into heat.

However, since another inherent characteristic of high frequency current is to concentrate on the surface of its conductor, only the surface layers become heated. This tendency, called “skin effect”, is a function of the frequency and, other things being equal, higher frequencies are effective at shallower depths. The frictional action producing the heat is called hysteresis and is obviously dependent upon the magnetic qualities of the steel. Thus, when the temperature has passed the critical point at which the steel becomes non-magnetic, all hysteretic heating ceases.

There is an additional source of heat due to eddy currents which flow in the steel as a result of the rapidly changing flux in the field. With resistance of the steel increasing with temperature, the intensity of this action is decreased as the steel becomes heated, and is only a fraction of its “cold” original value when the proper quenching temperature is reached.

When the temperature of an inductively heated steel bar arrives at the critical point, heating due to eddy currents continues at a greatly reduced rate. Since the entire action goes on in the surface layers, only that portion is affected. The original core properties are maintained, the surface hardening being accomplished by quenching when complete carbide solution has been attained in the surface areas. Continued application of power causes an increase in depth of hardness, for as each layer of steel is brought to temperature, the current density shifts to the layer beneath which offers a lower resistance. It is obvious that the selection of the proper frequency, and control of power and heating time will make fulfillment of any desired specifications of surface hardening possible.

Metallurgy of Induction Heating

The unusual behavior of steel when heated inductively and the results obtained merit a discussion of the metallurgy involved. Carbide solution rates of less than a second, higher hardness than that produced by furnace treatment, and a nodular type of martensite are points of consideration

that classify the metallurgy of induction hardening as “different”. Further, surface decarburization and grain growth do not occur because of the short heating cycle.

Induction heating

Induction heating produces a hardness that is maintained through 80 percent of its depth, and from there on, a gradual decrease through a transition zone to the original hardness of the steel as found in the core which has not been affected. The bond is thus ideal, eliminating any chance of spalling or checking.

Complete carbide solution and homogeneity as evidenced by maximum hardness can be accomplished with a total heating time of 0.6 second. Of this time, only 0.2 to 0.3 second is actually above the lower critical. It is interesting to note that induction hardening equipment is in every day operation on a production basis with complete carbide solution, resulting from a heating and quenching cycle, the total time of which is less than 0.2 second.

The fine nodular and more homogeneous martensite which results from the induction hardening is more readily apparent with carbon steels than with alloy steel because of the nodular appearance of most alloy martensite. This fine structure must have for its origin an austenite which is the result of a more thorough carbide diffusion than is obtained with thermal heating. Practically instantaneous development of critical temperatures throughout the entire microstructure of the alpha iron and iron carbide is particularly conducive to rapid carbide solution and a distribution of constituents which has as its inevitable product a thoroughly homogeneous austentite. Further, the conversion of this structure to martensite will produce a martensite which possesses similar characteristics and a corresponding resistance to wear or penetrating instruments.

high speed heating by induction

high speed heating by induction

The heating is accomplished by use of high frequency currents. Specifically chosen frequencies from 2,000 to 10,000 cycles and upwards of 100,000 cycles are being used extensively at the present time. Current of this nature in flowing through an inductor produces a high-frequency magnetic field within the region of the inductor. When a magnetic material such as steel is placed within this field, there is a dissipation of energy in the steel which produces heat. The molecules within the steel attempt to align themselves with the polarity of this field, and with this changing thousands of times per second, an enormous amount of internal molecular friction is developed as a result of the natural tendency for the steel to resist changes. In this manner the electrical energy is transformed, through the medium of friction, into heat.

However, since another inherent characteristic of high frequency current is to concentrate on the surface of its conductor, only the surface layers become heated. This tendency, called “skin effect”, is a function of the frequency and, other things being equal, higher frequencies are effective at shallower depths. The frictional action producing the heat is called hysteresis and is obviously dependent upon the magnetic qualities of the steel. Thus, when the temperature has passed the critical point at which the steel becomes non-magnetic, all hysteretic heating ceases.

There is an additional source of heat due to eddy currents which flow in the steel as a result of the rapidly changing flux in the field. With resistance of the steel increasing with temperature, the intensity of this action is decreased as the steel becomes heated, and is only a fraction of its “cold” original value when the proper quenching temperature is reached.

When the temperature of an inductively heated steel bar arrives at the critical point, heating due to eddy currents continues at a greatly reduced rate. Since the entire action goes on in the surface layers, only that portion is affected. The original core properties are maintained, the surface hardening being accomplished by quenching when complete carbide solution has been attained in the surface areas. Continued application of power causes an increase in depth of hardness, for as each layer of steel is brought to temperature, the current density shifts to the layer beneath which offers a lower resistance. It is obvious that the selection of the proper frequency, and control of power and heating time will make fulfillment of any desired specifications of surface hardening possible.

Metallurgy of Induction Heating

The unusual behavior of steel when heated inductively and the results obtained merit a discussion of the metallurgy involved. Carbide solution rates of less than a second, higher hardness than that produced by furnace treatment, and a nodular type of martensite are points of consideration

that classify the metallurgy of induction hardening as “different”. Further, surface decarburization and grain growth do not occur because of the short heating cycle.

The heating is accomplished by use of high frequency currents. Specifically chosen frequencies from 2,000 to 10,000 cycles and upwards of 100,000 cycles are being used extensively at the present time. Current of this nature in flowing through an inductor produces a high-frequency magnetic field within the region of the inductor. When a magnetic material such as steel is placed within this field, there is a dissipation of energy in the steel which produces heat. The molecules within the steel attempt to align themselves with the polarity of this field, and with this changing thousands of times per second, an enormous amount of internal molecular friction is developed as a result of the natural tendency for the steel to resist changes. In this manner the electrical energy is transformed, through the medium of friction, into heat.

However, since another inherent characteristic of high frequency current is to concentrate on the surface of its conductor, only the surface layers become heated. This tendency, called “skin effect”, is a function of the frequency and, other things being equal, higher frequencies are effective at shallower depths. The frictional action producing the heat is called hysteresis and is obviously dependent upon the magnetic qualities of the steel. Thus, when the temperature has passed the critical point at which the steel becomes non-magnetic, all hysteretic heating ceases.

There is an additional source of heat due to eddy currents which flow in the steel as a result of the rapidly changing flux in the field. With resistance of the steel increasing with temperature, the intensity of this action is decreased as the steel becomes heated, and is only a fraction of its “cold” original value when the proper quenching temperature is reached.

When the temperature of an inductively heated steel bar arrives at the critical point, heating due to eddy currents continues at a greatly reduced rate. Since the entire action goes on in the surface layers, only that portion is affected. The original core properties are maintained, the surface hardening being accomplished by quenching when complete carbide solution has been attained in the surface areas. Continued application of power causes an increase in depth of hardness, for as each layer of steel is brought to temperature, the current density shifts to the layer beneath which offers a lower resistance. It is obvious that the selection of the proper frequency, and control of power and heating time will make fulfillment of any desired specifications of surface hardening possible.

Metallurgy of Induction Heating

The unusual behavior of steel when heated inductively and the results obtained merit a discussion of the metallurgy involved. Carbide solution rates of less than a second, higher hardness than that produced by furnace treatment, and a nodular type of martensite are points of consideration

that classify the metallurgy of induction hardening as “different”. Further, surface decarburization and grain growth do not occur because of the short heating cycle.

Induction heating produces a hardness that is maintained through 80 percent of its depth, and from there on, a gradual decrease through a transition zone to the original hardness of the steel as found in the core which has not been affected. The bond is thus ideal, eliminating any chance of spalling or checking.

Complete carbide solution and homogeneity as evidenced by maximum hardness can be accomplished with a total heating time of 0.6 second. Of this time, only 0.2 to 0.3 second is actually above the lower critical. It is interesting to note that induction hardening equipment is in every day operation on a production basis with complete carbide solution, resulting from a heating and quenching cycle, the total time of which is less than 0.2 second.

The fine nodular and more homogeneous martensite which results from the induction hardening is more readily apparent with carbon steels than with alloy steel because of the nodular appearance of most alloy martensite. This fine structure must have for its origin an austenite which is the result of a more thorough carbide diffusion than is obtained with thermal heating. Practically instantaneous development of critical temperatures throughout the entire microstructure of the alpha iron and iron carbide is particularly conducive to rapid carbide solution and a distribution of constituents which has as its inevitable product a thoroughly homogeneous austentite. Further, the conversion of this structure to martensite will produce a martensite which possesses similar characteristics and a corresponding resistance to wear or penetrating instruments.

Induction heating produces a hardness that is maintained through 80 percent of its depth, and from there on, a gradual decrease through a transition zone to the original hardness of the steel as found in the core which has not been affected. The bond is thus ideal, eliminating any chance of spalling or checking.

Complete carbide solution and homogeneity as evidenced by maximum hardness can be accomplished with a total heating time of 0.6 second. Of this time, only 0.2 to 0.3 second is actually above the lower critical. It is interesting to note that induction hardening equipment is in every day operation on a production basis with complete carbide solution, resulting from a heating and quenching cycle, the total time of which is less than 0.2 second.

The fine nodular and more homogeneous martensite which results from the induction hardening is more readily apparent with carbon steels than with alloy steel because of the nodular appearance of most alloy martensite. This fine structure must have for its origin an austenite which is the result of a more thorough carbide diffusion than is obtained with thermal heating. Practically instantaneous development of critical temperatures throughout the entire microstructure of the alpha iron and iron carbide is particularly conducive to rapid carbide solution and a distribution of constituents which has as its inevitable product a thoroughly homogeneous austentite. Further, the conversion of this structure to martensite will produce a martensite which possesses similar characteristics and a corresponding resistance to wear or penetrating instruments.  high speed heating by induction

high speed heating by induction