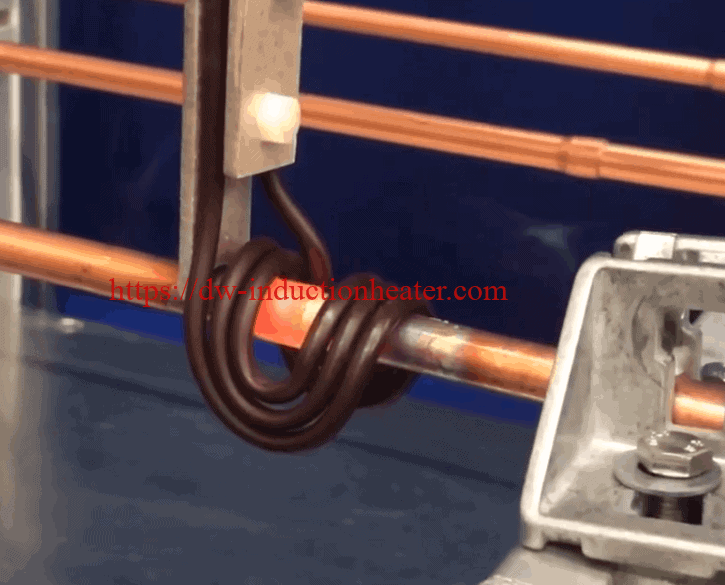

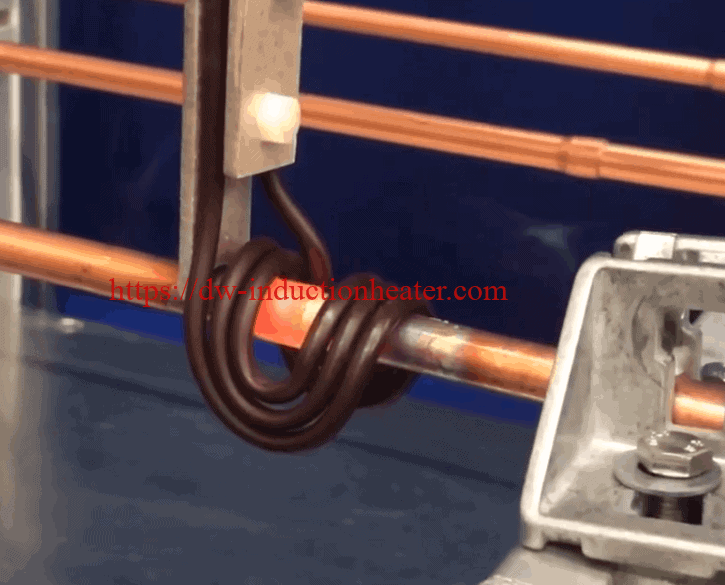

High Frequency Induction Brazing copper to copper pipes Process

Objective: Induction Brazing copper to copper pipes

Equipment: DW-UHF-6KW-III handheld induction brazing heater

Equipment: DW-UHF-6KW-III handheld induction brazing heater

Materials: Six Copper pipes (9.5 mm)

Power: 6 kW

Materials: Six Copper pipes (9.5 mm)

Power: 6 kW

Temperature: 1475 °F/ 800°C

Time: 20 seconds

Temperature: 1475 °F/ 800°C

Time: 20 seconds

Equipment: DW-UHF-6KW-III handheld induction brazing heater

Equipment: DW-UHF-6KW-III handheld induction brazing heater

Materials: Six Copper pipes (9.5 mm)

Power: 6 kW

Materials: Six Copper pipes (9.5 mm)

Power: 6 kW

Temperature: 1475 °F/ 800°C

Time: 20 seconds

Temperature: 1475 °F/ 800°C

Time: 20 seconds

Process:

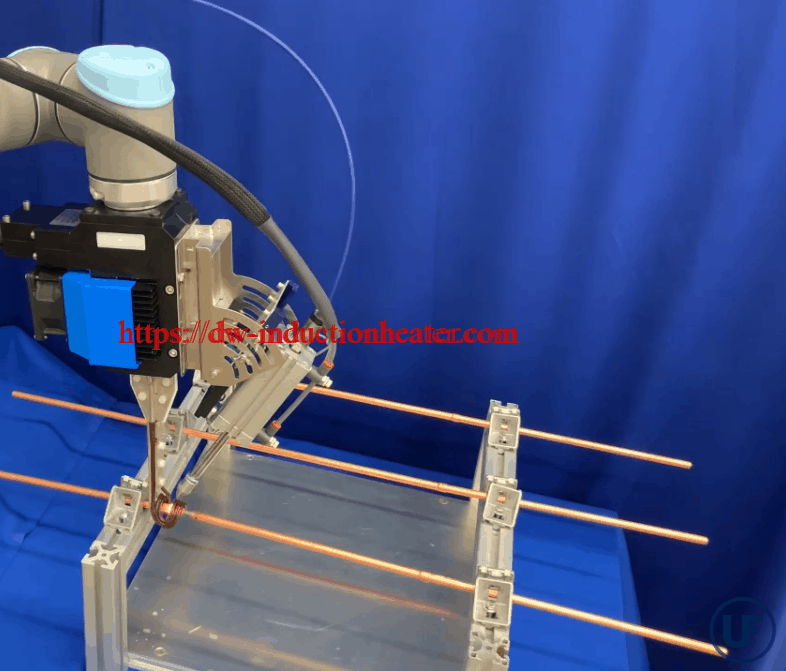

The DW-UHF-6KW-III handheld induction brazing system with robot can automatically induction braze multiple joints located in predefined positions. For this brazing application a wire feeder was mounted to the DW-UHF-6KW-III induction brazing heater, which feds the alloy onto the copper joints. A nitrogen nozzle was also added to reduce oxidization of the joints, this helps minimize the brazed joints cleaning procedure. The robotic system is programmed to move to each joint and apply power for a pre-programmed amount of time. This ensures a repeatable and reliable brazing process. The induction brazing of copper to copper was performed successfully within 20 seconds per joint at 1475 °F.

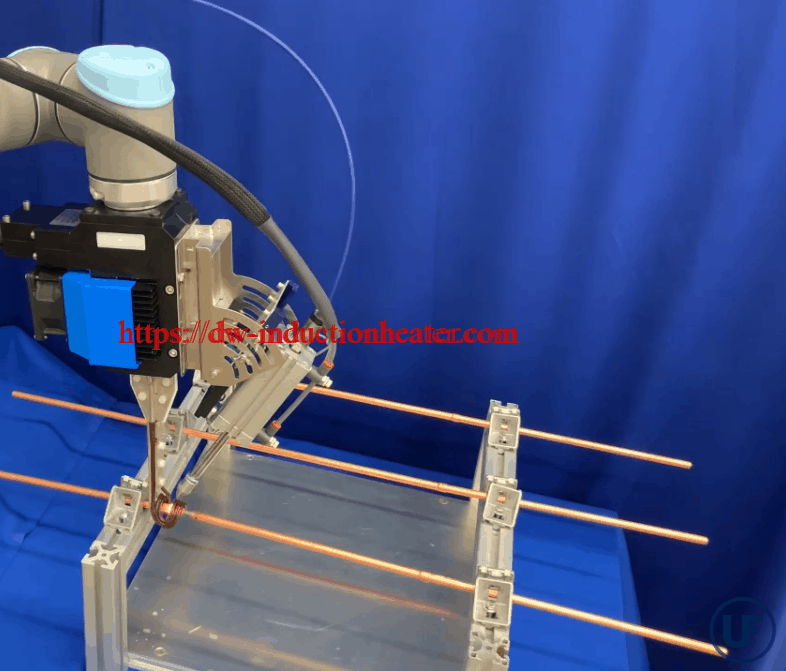

Process:

The DW-UHF-6KW-III handheld induction brazing system with robot can automatically induction braze multiple joints located in predefined positions. For this brazing application a wire feeder was mounted to the DW-UHF-6KW-III induction brazing heater, which feds the alloy onto the copper joints. A nitrogen nozzle was also added to reduce oxidization of the joints, this helps minimize the brazed joints cleaning procedure. The robotic system is programmed to move to each joint and apply power for a pre-programmed amount of time. This ensures a repeatable and reliable brazing process. The induction brazing of copper to copper was performed successfully within 20 seconds per joint at 1475 °F.

The DW-UHF-6KW-III handheld induction brazing heater is ideal for flameless brazing of refrigerator compressors, heat exchangers, home appliance components and complex HVAC assemblies.

The DW-UHF-6KW-III handheld induction brazing heater is ideal for flameless brazing of refrigerator compressors, heat exchangers, home appliance components and complex HVAC assemblies.