Induction Aluminum Brazing with Computer Assisted

Induction aluminum brazing is becoming more and more common in industry. A typical example is brazing various pipes to an automotive heat exchanger body. The

induction heating coil widely used for this type of process is non-encircling one, which can be referred to as “Horseshoe-hairpin” style. For these coils, the magnetic field and resulting eddy current distribution are inherently 3-D in nature. In these applications, there are problems with joint quality and consistency of the results from part to part. To solve one such problem for a large automotive manufacturer, Flux3D computer simulation program was used for the process study and optimization. Optimization included changing the induction coil and magnetic flux controller configuration. New induction coils, which have been experimentally validated in a laboratory, produce parts with higher quality joints in several production sites.

Each car requires several different heat exchangers (heater cores, evaporators, condensers, radiators, etc.) for powertrain cooling, air conditioning, oil cooling, etc. The vast majority of the passenger car heat exchangers today are made of aluminum or aluminum alloys. Even if the same engine is used for several automobile models, the connections can vary due to different layouts under the hood. For this reason, it is standard practice for parts manufacturers to make several basic heat exchanger bodies and then attach different connectors in a secondary operation.

Heat exchanger bodies usually consist of aluminum fins, tubes and headers brazed together in a furnace. After brazing, heat exchangers are customized for the given car model by attaching either nylon tanks or most commonly different aluminum pipes with connection blocks. These pipes are attached either by MIG welding, flame or induction brazing. In the case of brazing, very precise temperature control is required due to the small difference in the melting and brazing temperatures for aluminum (20-50 C depending upon alloy, filler metal and atmosphere), high thermal conductivity of aluminum and short distance to other joints brazed in a previous operation.

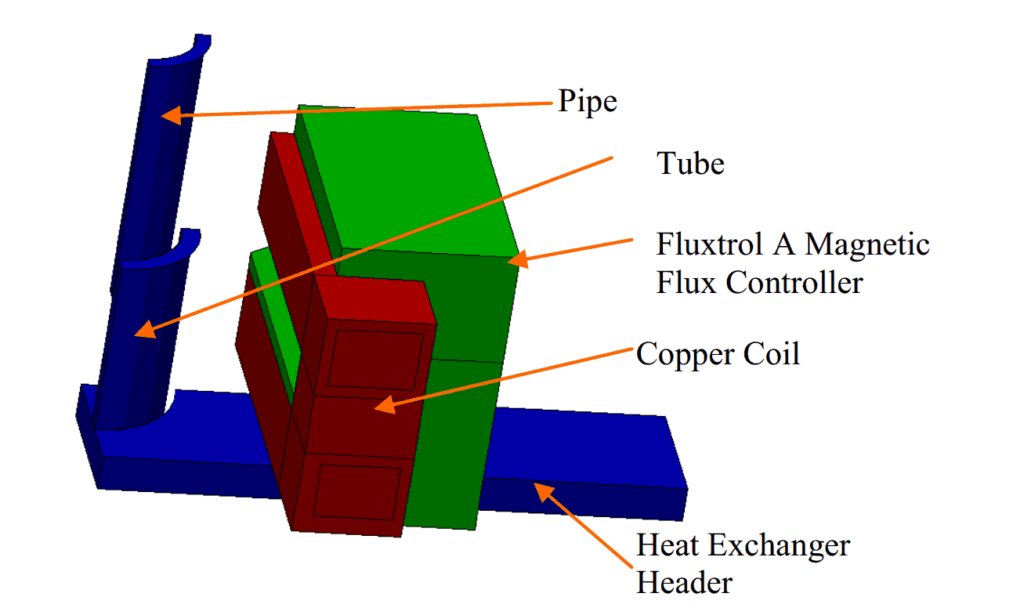

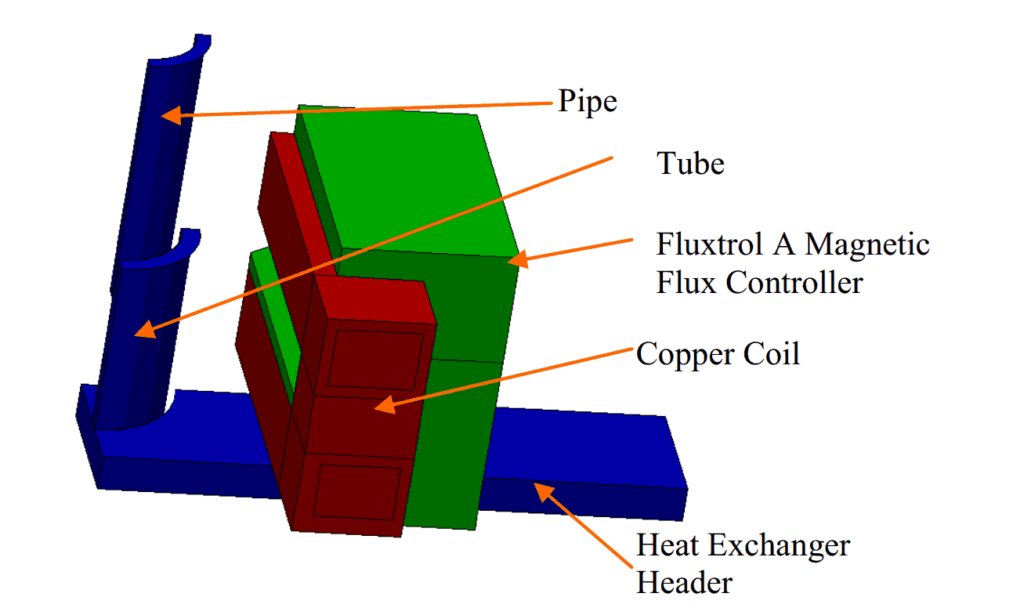

Induction heating is a common method for brazing various pipes to heat exchanger headers. Figure 1 is a picture of an

induction brazing set-up for brazing a pipe to a tube on a heat exchanger header. Due to the requirements for precise heating, the face of the induction coil must be in close proximity to the joint to be brazed. Therefore a simple cylindrical coil can not be used, because the part could not be removed after the joint is brazed.

There are two main induction coil styles used for brazing these joints: “clamshell” and “horseshoe-hairpin” style inductors. “Clamshell” inductors are similar to cylindrical inductors, but they open to allow part removal. “Horseshoe-hairpin” inductors are shaped like a horseshoe for loading the part and are essentially two hairpin coils on opposite sides of the joint.

The advantage of using a “Clamshell” inductor is that the heating is more uniform in circumference and relatively easy to predict. The disadvantage of a “Clamshell” inductor is that the mechanical system required is more complicated and the high current contacts are relatively unreliable.

“Horseshoe-hairpin” inductors produce more complicated 3-D heat patterns than “Clamshells”. The advantage of a “Horseshoe-hairpin” style inductor is that the part handling is simplified.

[caption id="attachment_6409" align="alignnone" width="1024"]

Induction Aluminum Brazing[/caption]

Computer simulation optimizes brazing

A large heat-exchanger manufacturer was having quality problems with brazing the joint shown in Fig. 1 using a horseshoe-hairpin style inductor. The braze joint was good for the majority of parts, but heating would be totally different for some parts, resulting in insufficient joint depth, cold joints and filler metal running up the pipe wall due to local overheating. Even with testing of each heat exchanger for leaks, some parts still leaked at this joint in service. Centre for Induction Technology Inc. was contracted to analyze and solve the problem.

The power supply used for the job has a variable frequency of 10 to 25 kHz and rated power of 60 kW. In the brazing process, an operator installs a filler metal ring on the pipe end and inserts the pipe inside the tube. A heat exchanger is placed onto a special rig and moved inside the horseshoe inductor.

The entire brazing area is prefluxed. The frequency used to heat up the part typically is 12 to 15 kHz, and heating time is around 20 seconds. The power level is programmed with linear reduction at the end of the heating cycle. An optical pyrometer turns off the power when the temperature on the back side of the joint reaches a preset value.

There are many factors that can cause the inconsistency the manufacturer was experiencing, such as variation in joint components (dimensions and position) and unstable and variable (in time) electrical and thermal contact between the tube, pipe, filler ring, etc. Some phenomena are inherently unstable, and small variations of these factors can cause different process dynamics. For example, the open filler metal ring can partially unwind under the electromagnetic forces, and the free end of the ring may be sucked back by capillary forces or remained unmelted. The noise factors are difficult to reduce or eliminate, and the solution to the problem required increasing the robustness of the total process. Computer simulation is an effective tool to analyze and optimize the process.

During the evaluation of the brazing process, strong electrodynamic forces were observed. At the moment the power is turned on, the horseshoe coil clearly experiences an expansion due to a sudden application of electrodynamic force. Thus, the inductor was made mechanically stronger, including incorporating an additional fiberglass (G10) plate connecting the roots of two hairpin coils. The other demonstration of electrodynamic forces present was the shifting of molten filler metal away from the areas close to copper turns where the magnetic field is stronger. In a normal process, filler metal distributes uniformly around the joint due to capillary forces and gravity in contrast to an abnormal process where filler metal may run out of the joint or move up along the pipe surface.

Because

induction aluminum brazing is a very complicated process, it is not feasible to expect an accurate simulation of the whole chain of mutually coupled phenomena (electromagnetic, thermal, mechanical, hydrodynamic and metallurgical). The most important and controllable process is the generation of electromagnetic heat sources, which were analyzed using the Flux 3D program. Due to the complex nature of the induction brazing process, a combination of computer simulation and experiments was used for process design and optimization.

Induction_Aluminum_Brazing with Computer_Assisted

Induction_Aluminum_Brazing with Computer_Assisted

Induction Aluminum Brazing[/caption]

Induction Aluminum Brazing[/caption]

Induction_Aluminum_Brazing with Computer_Assisted

Induction_Aluminum_Brazing with Computer_Assisted