2022年7月17日星期日

Heating Aluminum Foil For Cap Sealing

Induction Heating Aluminum Foil For Cap Sealing with IGBT inductive heater

Objective An induction heater is used to heat a polymer laminated aluminum foil in 0.5 to 2.0 seconds. The heat produced in the aluminum foil melts the polymer that bonds to the neck of a plastic container.

Material Aluminum foil, polyethylene, polypropylene, polyvinylchloride, polystyrene, polyethylene terephthalate, styrene acrylonitrile

Temperature 300 - 400 (ºF), 149 - 204 (ºC)

Frequency 50 to 200 kHz

Equipment DAWEI solid-state induction power supplies operating between 1 & 10 kW at frequencies of 50- 200 kHz. These units operate with remote sealing heads which allows the main power cabinet of the equipment to be located away from the immediate production area. Distances of up to 100 meters are possible. The microprocessor is used to control

and protect the system and ensures that the optimal operating frequency is maintained at all times and that each container

receives the same amount of heat energy from cycle to cycle.

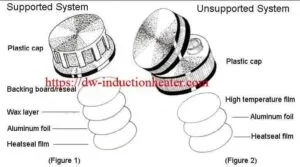

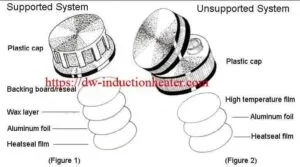

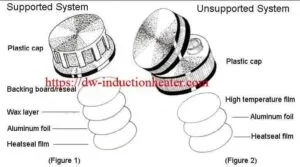

Process Two different types of aluminum foil laminates are available for this application. The first assembly includes backing

board/reseal, a wax layer, aluminum foil, and a heatseal film for supported systems (Figure 1). The second assembly includes a high temperature film, aluminum foil, and a heatseal film for unsupported systems (Figure 2). The procedure is to fit the foil membrane into the cap and to fit the cap to the container after the product is filled.

Results For the aluminum foil assembly as shown in Figure 1, heat induced in the metallic foil by the induction coil almost

instantaneously melts the polymer coating and the neck of the container forming a hermetic seal between the heat seal film

and the rim of the container. The heat also melts the wax between the aluminum foil and the back board. The wax is

absorbed into the back board. This results in an air tight bond between the aluminum foil/membrane and the rim of the

container, the back board is released and remains in the cap.

Process (cont’d) In the case of unsupported membranes in Figure 2, one side of the aluminum foil is coated with a heat sealable polymer film and this face that will be in contact with and sealed to the container. The other side of the foil that will be in contact with the cap has a higher melting-point film that prevents adhesion of the aluminum to the cap allowing the end user to unscrew the cap. Unsupported membranes are typically used where the end user pierces the tamper evident membrane prior to dispensing the product. The aluminum foil acts as a vapor barrier preserving the freshness of the product and prevents it from drying.

关注者

博客归档

-

▼

2022

(1729)

-

▼

七月

(87)

- Induction Hot Plate

- Induction Shrink Fitting For Inserts

- Induction Soldering Stainless Steel Tubes to Brass...

- induction brazing and soldering technology

- induction brazing stainless steel tubing process

- Induction Brazing Machine

- Induction Brazing Basics

- Induction Brazing Copper Assembly

- induction heating steel casting

- Induction Soldering Wire of Co-axial

- Induction Bar End Heating Furnace

- Induction Annealing Brass Bullet Shells

- Induction Brazing Carbide Onto Steel Part

- induction small copper tubing brazing connection j...

- Induction Preheating Hot Rod Heading

- High Frequency Induction Brazing Diamond Inserts

- induction brazing stainless steel to steel

- Induction Brazing Carbide to Steel

- Induction Brazing Carbon Steel Filter

- induction brazing carbide tip onto steel head teeth

- Induction Brazing T Shaped Copper Tubing Assemblies

- Induction Hardening and tempering

- Handheld Induction Brazing HVAC Pipes of Heat Exch...

- Billet Heating Furnace with Induction Heating

- Induction annealing copper wires

- Aluminum Billet Heating Furnace

- Brazing Copper Assemblies With Induction

- Brazing Carbide-Steel Tool with Induction

- Brazing Carbide to Steel Part With Induction Heating

- Induction Annealing Brass Bullet Shells

- Induction Soldering Wire of Co-axial

- Heating Shrink Fitting Camshaft Gear

- Induction Brazing Steel Tips

- What is induction welding?

- Induction Soldering Brass to Steel Plate

- induction heating for surface quenching of steel

- Induction Soldering Brass Assembly

- Induction Brazing Aluminum to Aluminum Tube

- induction brazing and soldering technology

- Induction Heating Molding Catheter Tip

- Induction Brazing Aluminum Tube T Joints

- Induction Hardening and tempering

- Heating Aluminum Foil For Cap Sealing

- What is induction welding?

- Brazing Joining Copper Connectors With Induction

- Induction Brazing Carbide Onto Steel Part

- Induction Drying Grain with Induction Heating method

- ultrasonic plastic welder for US plastic welding b...

- Jointing Metal with Brazing and Welding

- Induction Aluminum Brazing with Computer Assisted

- high frequency induction soldering wire to connector

- Soldering Antenna Wire With Induction

- Induction Brazing Steel To Carbide Plate

- Induction Annealing Copper Wire

- handbook of induction heating eddy current

- principle of electromagnetic induction heating

- ultrasonic plastic welder for US plastic welding b...

- Induction Preheating Steel Tubes

- Induction Brazing T Shaped Copper Tubing Assemblies

- induction brazing and soldering technology

- induction brazing and soldering technology

- Induction Brazing Steel Parts to Tungsten Carbide ...

- Brazing Carbide-Steel Tool with Induction

- Ultrasonic Plastic Welding Machine For Bonding The...

- induction hardening steel handheld stamps

- Induction Bending Pipe-Tube

- Induction Soldering Stainless Steel Tubing

- induction heating process with inert gas and vacuu...

- Induction Soldering Steel Parts

- Induction Annealing Steel Wire

- induction surface hardening steel screws

- Induction Spring Heating Application

- Induction Brazing Aluminum to Aluminum Tube

- Heating Shrink Fitting Camshaft Gear

- Induction Bending Pipe-Tube

- Induction Heating Coils Design and Basic PDF

- Induction Brazing Heating Exchanger Copper Pipes

- Induction Soldering Steel Cover

- induction heating diffusion pump with electromagne...

- Induction Soldering Wires Onto Connection

- Induction Heating Plasma

- induction brazing automotive copper heating exchan...

- induction brazing stainless steel to steel

- Induction Fluid Pipeline heating system

- induction heating diffusion pump with electromagne...

- Brazing Silver To Copper With Induction

- induction surface hardening steel screws

-

▼

七月

(87)

我的简介

- HLQ induction heating machine

- HLQ induction heating machine manufacturer provides the service of induction brazing,melting,hot forming,hardening surface,annealing,shrink fitting,PWHT,etc.